Sales figures and the willingness of industries to invest in additive manufacturing of metal prove that this technologies possibilities and importance are growing:

- Investments: A study of KMPG, an auditing company in Germany, shows that nearly 25% of managers in metal sectors invest in additive manufacturing and 27 % of industries which already have such technologies plan to increase their capacities.

- Market Growth: Wohlers Associates,show that while 3D printing has grown approximately 26% in 2015, metal 3D printing has grown 48% in sold machines and 34% in sold materials

(Source: IDTechEx).

Meanwhile, the continuous further developments of the technology open concrete fields of application in numerous industries. In addition to pure prototyping, metal 3D printing is used in industrial production

Applications of Direct 3D Metal Printing

Generally, there are three essential functional fields of application in direct metal 3D printing technologies:

- Rapid Prototyping:The rapid production of single parts or small series for product developments or researches.

- Rapid Tooling:The production of tools for different casting methods.

- Rapid Manufacturing:Direct production of parts for products which are available in the market.

All above-named terms, which established in recent years, contain “rapid” in their name. This applies on the one hand because the process is very quick (getting a physical model from a CAD model) and on the other hand the relatively long printing time is one of the most important reasons, why the technology isn’t used on a larger scales in industry yet. However, some industrial applications already exist:

- Medical technology: More and more individualized products (specific for patients) with complex free forms are required. Compared to conventional methods, direct Metal 3D Printing offers essential advantages and is used in dentistry (e.g. parts of implants, crowns and bridge frameworks) or in surgery, e.g. implants or templates.

- Military technology: How it is always with new technologies, also direct metal 3D printing is used for military. Advantages are realizable savings of weight and the possibility of fast location-independent productions. The latter goes from functioning pistols (image), parts or even (almost) complete flying object to munitions.

- Automobile industry: Additive manufacturing of metal didn’t establish in industrial production for automobiles yet. But there are some subareas in which this technology is used. For example, the production of prototypes or of special-purpose vehicles, especially in racings like Formula 1. An increasing trend is still the spare parts production via 3D printing

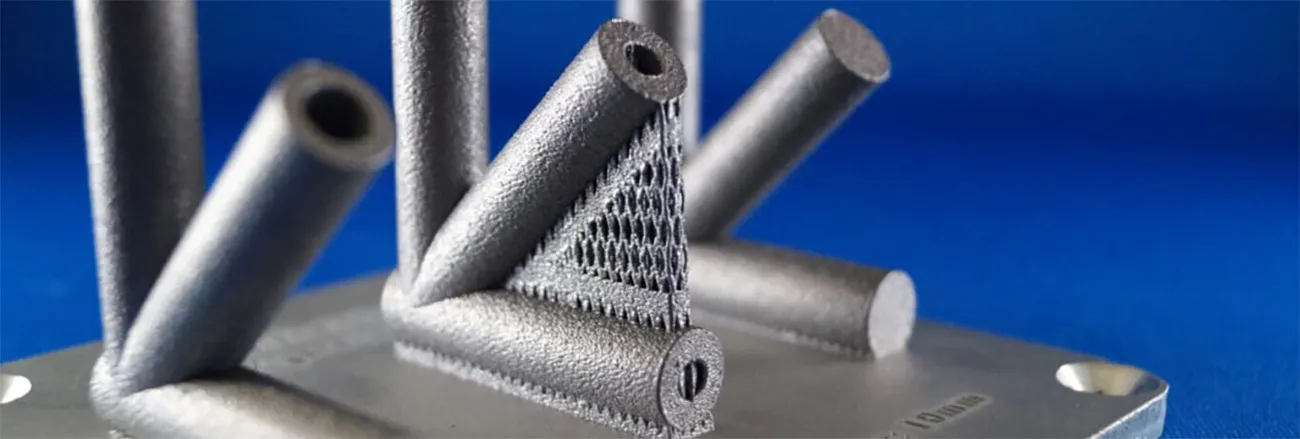

– Especially Daimler leads the way. - Aerospace Engineering: In this area very complex and production designs can be simplified because of high design freedom (e.g. by innovative structures – compare image). So not only costs but also weight can be saved. In GE Turbines

serial 3D printed metal parts are already plugged.

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Weitere Informationen

Sie sehen gerade einen Platzhalterinhalt von Standard. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf den Button unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Weitere InformationenMedicine technology: Case Study of Renishaw about use of 3d printed metal parts in medical technology. Source: Renishaw.

Militry technology: Test of a widely 3D printed drone of Royal Navy. Source: Univers.

Automobile industry: Use of direct 3D metal printing technology of auto brand Koenigssegg. Source: Koenigsegg.

Aerospace Engineering: Example of a leight weight construction of metal. Source: 3Faktur.

The most important 3D Printing methods

Most common methods

Selective Laser Sintering (SLS) or Selective Laser Melting (SLM):

- Functionality: Metal powder is spread over a platform. The Laser sinters or melts a layer in powder bed. The platform goes down and a new layer of powder can be applied and sintered by lasing. By lasing, the layers also get linked together.

- Variations: While Sintering, the powder is warmed up until shortly before the melting point and while melting, this point is exceeded. Sintered parts are slightly porose (insofar often lighter) therefore parts which are produced with SLM are in relation to material characteristics similar to the raw materials.

- Materials: Most used tools are of Aluminum, Titanium, Stainless Steel or Tool Steel and Cobal-Chrome Alloys.

- Producer of 3D printers e.g. EOS, SLM Solutions, Concept Laser, Renishaw or TRUMPF

- Advantages: Manufacturing of raw materials or typically industrial used alloys. Very resistent parts with relatively consistent material characteristics.

- Further resources: SLM Direct Metal 3D Printing – The technology (internal link).

Metal Binder Jetting:

- Functionality:The most common combination is Stainless Steel and Bronze, but also iron, chrome or cobalt alloy are available.

- Materials:The most common combination is Stainless Steel and Bronze, but also iron, chrome or cobalt alloy are available.

- Producers of 3D printers: ExOne developed this technology and is considered as unchallenged market leader.

- Advantages:Supporting Structures aren’t necessary so you have a freedom of designing. Generally, the printing times of Metal Binder Jetting is very short.

- Further resources: What is Binder Jetting (Extern – ExOne).

Examples for SLM printed components (Left: Aluminum; middle: Titanium; right: Stainless Steel 1.4404).

Further Methods

- Electron beam melting (EBM): Basically it functions similar to SLM/SLS but here, a electron beamish used instead of laser. Arcam, a Swedish company, developed this technology. This method is very time-consuming and cost-intensive. But you can get more accurate and stable parts with this technology than with SLS/SLM.

- Binder Jetting von Formen:This technology, also offered by ExOne, allows printing sand molds for metal. You can even print molds with more than 2m length.

Newer Methods

- NanoParticle Jetting:The israeli industry Xjet developed this technology and is waiting to bringing it onto the market (Status Nov. 2016). Here, metal nanoparticles are dissolved in a liquid and are applied on a platform via printhead. Trough heat the liquid evaporates and the metal is left over and united. The layers are just 2 µm high, so this technology is considered as the most detailed one for printing metal.

Conclusion: There is no clear standard. There are numerous technologies, each with advantages but also disadvantages. In order to use metal 3D printing for industry the costs and printing time of machines have to be reduced.

About 3Faktur: 3Faktur specializes in 3D printing, rapid prototyping, and rapid manufacturing. We utilize HP’s Multi Jet Fusion technology and offer various materials for prototyping and series production. If you have any questions about your project, feel free to contact us.