Additive manufacturing methods are taking an increasingly prominent place in industrial production. Although some of these technologies have been around for 30 years, the most spectacular developments have occurred in recent years. In this article, we will discuss the most significant advantages of 3D printing compared to “traditional” manufacturing methods. Of course, 3D printing cannot completely replace established technologies, but being aware of the benefits of 3D printing can help you make better decisions regarding the choice of manufacturing method.

Preface: Private vs. Industrial Applications of 3D Printing

3D printing is still primarily an industrial technology (additive manufacturing). However, private use of 3D printers is also increasing significantly. Nowadays, a multiple number of private 3D printers (often priced from a few hundred to a thousand euros) are sold compared to industrial systems, which typically cost several hundred thousand euros.

Applications in the private sector are mainly in model making and DIY applications. The advantages are evident, as hobbyists now have a tool at their disposal to freely design and produce components and other objects.

In the industrial sector, the advantages are more complex, as additive manufacturing is one of several manufacturing methods. The properties of 3D printing technology listed here mainly refer to industrial 3D printing.

Find more statistics at Statista Figure: Sales of 3D printers are increasing rapidly. The majority of sold machines are now devices for private users.

Advantages of 3D Printing – Overview

Manufacturing Time

The most prominent advantage of additive manufacturing is the high speed at which objects can be produced. This applies whether the objects have complex geometries or are relatively simple. Design and manufacturing processes that used to take days or weeks can now be completed within hours using 3D printing technologies. This is possible because certain process steps are no longer needed. The development and production of tools/molds are completely eliminated. Corrections to prototypes or last-minute design changes are also easily possible.

Typical lead times:

- Injection Molding: First, a tool (injection mold) is designed and manufactured (usually with CNC technology). The time span from order to the first product often takes weeks to months. The production time per component is significantly shorter than in 3D printing, but the path to get there is more elaborate.

- Machining: Production requires the creation of a program, which often takes several hours. The lead time theoretically can be short and completed in a few days. However, since the machines usually operate under high load (production of 1 part/cycle), the process typically takes a few weeks.

- 3D Printing: The manufacturing times for most 3D printing service providers are 1 – 2 weeks. The lead times vary slightly depending on the technology, e.g.:

- Multi Jet Fusion: The printing process typically takes 16 hours. Subsequently, there is a slow cooling phase that lasts about two days. The post-processing of the parts takes about one working day. Consequently, the shortest production time is three days. However, typically 150 – 300 parts are produced simultaneously per print run. More information about the technology.

- FDM: Usually, only one part is produced per cycle with this technology. A printing cycle usually takes a few hours (rule of thumb: printing time approx. 1 hour per cm of component height). Therefore, it is possible to manufacture components “overnight,” but only in very small quantities. More information about the process.

Production Costs

The reduction in production time already noticeably reduces development and production costs. But additive manufacturing has even more potential for cost reduction. To produce workpieces, no tools (e.g., for injection molding) or programs (e.g., for CNC) need to be created; the CAD file alone is (usually) sufficient. Tools can also be 3D printed directly.

Currently, additive manufacturing is only an option for mass production under certain circumstances. In general, “series production” in generative manufacturing involves batch sizes of 100 – 2,000 pieces, rarely more. (Small) series production in 3D printing usually involves laser sintering, HP Multi Jet Fusion, or, less commonly, FDM. In our article Laser Sintering vs. Injection Molding, we have summarized some practical examples that may make it easier for you to make the right decision.

Regarding the processes, there are, however, very significant differences. While an FDM print in PLA is often available for a few euros, the costs for a 3D print in titanium are often 30 – 50 times higher for the same model. In the plastic sector, FDM is often the cheapest method, followed by HP Jet Fusion, laser sintering, and stereolithography (more on the comparison in our article Laser Sintering vs. Stereolithography). Due to high material costs and long printing times (layer heights of about 15 µm), polyjet is usually the most cost-intensive plastic 3D printing process.

Risk Reduction

While even small changes to a workpiece or mold in casting processes already cause noticeable costs and more significant time investment, such changes can be easily and at low cost realized in 3D printing processes. By producing rapid and cost-effective prototypes, the product can be perfected, significantly reducing the risk of faulty production.

Customization

Products in mass production are characterized by their uniformity, as they are all cast with the same mold, for example. In particular, in the medical field and specifically in dental applications, individual solutions are required, making 3D printing a beneficial alternative. In the world of jewelry and fashion, too, 3D printing can contribute to standing out (see Adidas). Customizations and small series can also be realized with only minor changes to the 3D model.

Design Freedom

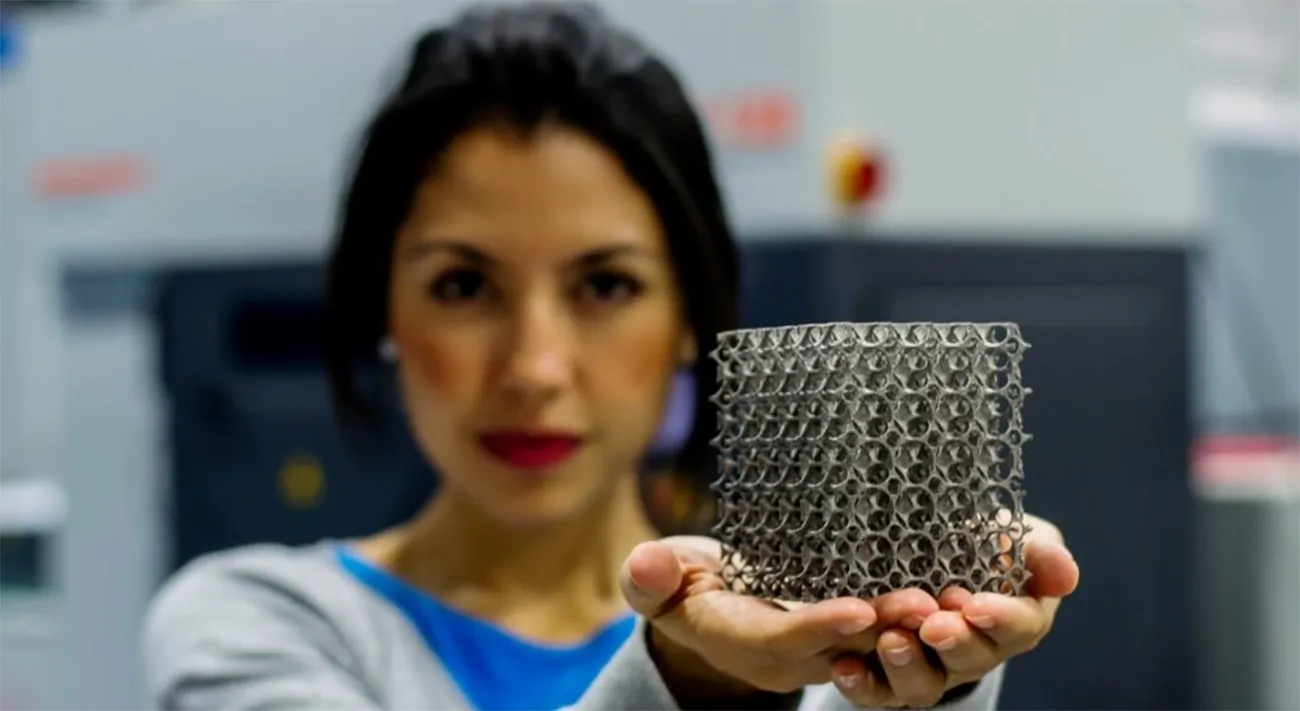

Depending on the process, very complex geometries can be produced in 3D printing. This is especially true for laser sintering and HP Jet Fusion, for which almost all restrictions that designers previously faced (with traditional manufacturing methods) are almost completely eliminated. Undercuts, cavities, holes changing direction, complex geometries, or large overhangs, everything is now almost effortlessly possible. 3D printing has swept away a large part of the design restrictions. Of course, some limitations remain, such as minimum wall thicknesses, build sizes, minimum distance between objects (more on this in our design guidelines). Furthermore, preparing the 3D model offers the possibility to design the model cost-optimally.

Sustainability

One advantage of 3D printing often remains underestimated, but it is of enormous importance. When producing workpieces using a 3D printing process, significantly less “waste” is generated compared to conventional production methods. In most cases, the amount of material used is also much lower since, apart from processes that use support material, all material “flows” into the object. The unused powder in the color jet process and the metal powder from sintering or melting can be almost completely recycled and used for new 3D prints.

The decentralized production made possible by 3D printing also reduces the transport routes necessary to turn an idea into a product.

Additional Key Advantages of 3D Printing

- Objects are freely scalable: Particularly interesting for architecture and visual models.

- Lightweight structures: 3D printing offers promising possibilities for lightweight construction for designers.

- Manufacturing On-Demand: No need for inventory storage, and quick changes are possible.

- Experimentation: Test prints and experiments can be realized inexpensively.

Summary

The use of 3D printing technologies offers many advantages. The production is fast, resource-efficient, and cost-effective for models/prototypes and small series. There are many new opportunities in the areas of design and lightweight constructions, and customization of production can be realized with little effort.

If you would like to learn more about 3D printing and its benefits, take a look at our overview page “3D Printing Basics and Guides” or contact us directly.

About 3Faktur: 3Faktur specializes in 3D printing, rapid prototyping, and rapid manufacturing. We utilize HP’s Multi Jet Fusion technology and offer various materials for prototyping and series production. If you have any questions about your project, feel free to contact us.