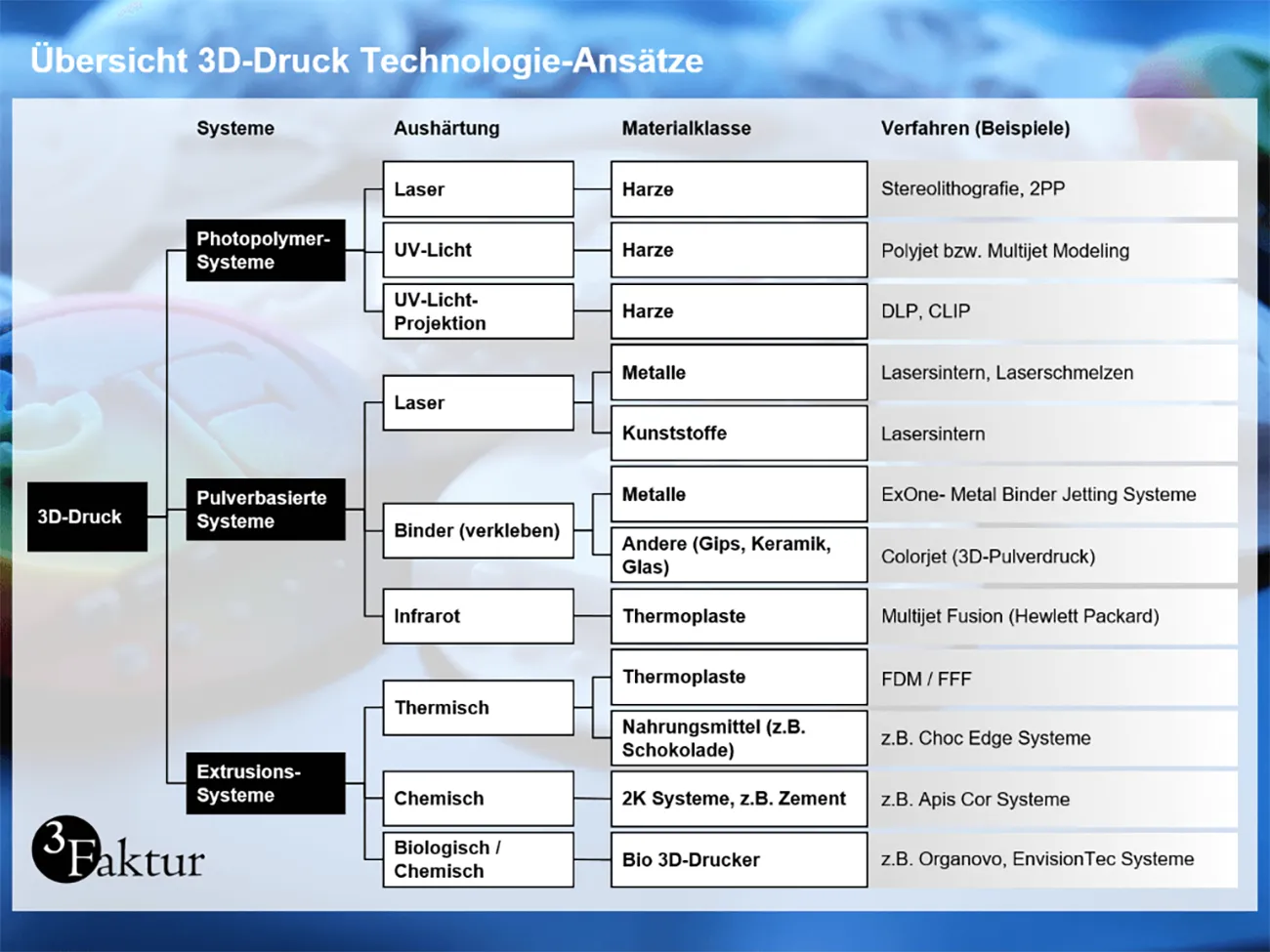

Image: Overview of 3D printing processes: For detailed view click here!

Under the term 3D printing, a lot of technologies have now “accumulated”. These processes differ in terms of the raw material used and the processing method. However, these technologies often rely on the same basic principles. Consequently, not every new process is necessarily a ‘revolution’, but mostly a further development or modification of already existing 3D printing technologies.

This short article provides a small (incomplete) overview of the most commonly used approaches.

Approaches in 3D Printing Technology

Currently, three main directions have emerged in 3D printing. These are powder-based 3D printing, systems based on material extrusion, and systems that work with photopolymers. In addition, there are other methods that can be classified as 3D printing technologies (e.g., Laminated Object Manufacturing), but these have not yet gained the same significance in the industry as the first three mentioned.

Powder-Based 3D Printing

There are generally three approaches here: the most well-known are ColorJet 3D printing and laser sintering (SLS) or melting (SLM). The former works chemically (bonding), while the latter processes are thermal (laser-based).

The ColorJet process uses a chemical binder (glue) to shape polymer gypsum. The binder contains pigments, allowing objects to be directly printed in color. The advantage of bonding is that it is irrelevant which material the powder is made of. Thus, with a comparable technology, sand molds for metal casting (e.g., Voxeljet, ExOne), metals (ExOne), or other materials such as ceramics, glass, or wood can be used.

In contrast, both laser sintering and laser melting processes work with lasers. Metal powder (SLS / SLM) or plastic powder (SLS) is solidified (melting or sintering) using a laser. The choice of powders is limited to thermoplastics and some metals (often steel, aluminum, or titanium).

Recently, HP introduced another system related to powder-based 3D printing. In the Multi Jet Fusion process, thermoplastics are initially wetted with a heat-conducting liquid and then sintered using infrared light. The result is parts that resemble those from laser sintering, but with higher density and therefore stability.

- Key advantages of powder-based processes: Very wide range of materials available and generally high production speeds (except for metals).

- Key disadvantages of powder-based processes: Objects are usually porous and the surfaces are accordingly rough.

Photopolymer Systems

In these processes, photosensitive resins are cured using a light source (UV light, laser). The most well-known methods are Stereolithography (SLA), Digital Light Processing (DLP), and the PolyJet process. In Stereolithography, a liquid resin is cured layer by layer using a (UV) laser. This process was in fact the very first rapid prototyping process, with developments starting in the 1970s. DLP systems operate on almost exactly the same principle, but instead of a laser, a projector is used. The advantage here is that much higher printing speeds can be achieved (a layer is completely cured by the projection), although individual pixels may still be visible depending on the resolution.

A new process (CLIP, a DLP-based process) is currently emerging in this technology field and promises to set new standards in terms of speed, as layers are completely eliminated and printing is continuous.

Polyjet systems (Stratasys) or Multijet Modeling (3D Systems) work slightly differently. The smallest droplets of resin are applied to a platform and immediately cured using a UV laser attached to the print head.

- Key advantages of liquid-based processes: Very smooth surfaces and high resolution.

- Key disadvantages of liquid-based processes: Limited range of materials (acrylics and epoxides) and often less mechanically robust.

Extrusion Systems

In these 3D printing systems, materials are extruded using an extruder and solidify through various means. By far the most important method is filament 3D printing (FDM or FFF), in which plastic (thermoplastics; often ABS, PLA, and polyamides) is melted in wire form and applied. Once applied, the plastic cools and solidifies. Newer methods use different materials for the plastics, such as ceramics or metals. In the case of the latter, Markforged and Desktop Metal have implemented new approaches. Metal powders are included in the filaments, which are sintered after printing.

Other systems are currently rather exotic and work, for example, with chemical curing (cement in house 3D printing, e.g., Apis-Cor) or even biologically (bio 3D printers, e.g., Organovo). These systems mostly work with print heads resembling syringes. With such systems, even food (e.g., Choc Edge) can now be printed.

- Key advantages of extrusion-based processes: Very large selection of materials and applications.

- Key disadvantages of extrusion-based processes: Often very slow and with limited surface quality.

About 3Faktur: 3Faktur specializes in 3D printing, rapid prototyping, and rapid manufacturing. We utilize HP’s Multi Jet Fusion technology and offer various materials for prototyping and series production. If you have any questions about your project, feel free to contact us.