Polyamide 12 (PA 12) is a rigid, high-strength plastic specifically developed for additive series production. PA 12 | Classic is our standard variant and has been continuously in our portfolio since 2017.

The powder marketed by HP under the trade name “HP 3D HR PA 12” is processed using the Multi Jet Fusion process. The resulting part impresses with high mechanical strength as well as thermal and chemical resistance – while maintaining attractive unit costs.

Quick Facts

Technology

Multi Jet Fusion

Colors

gray

black (dyed)

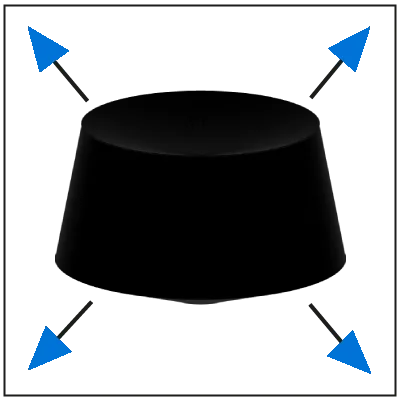

Build volume

min. 10 mm

max. 380 mm

Production time

3 working days (Priority)

6 working days (Standard)

12 working days (Flex)

Accuracy

± 0.3 %

(min. ± 0.3 mm)

PA 12 | Classic – our proven standard variant

From the raw material “HP 3D HR PA 12, enabled by Evonik” we manufacture three variants:

- PA 12 | Classic – proven standard quality

- PA 12 | Essential – cost-optimized entry-level solution

- PA 12 | Performance – optimized for the highest demands

PA 12 | Classic is our oldest variant and has been in continuous use since 2017. Hundreds of thousands of series parts prove its reliability. Printing is done in the “Balanced Mode” provided by HP with a layer thickness of 80 µm, the world’s most widely used print profile for Multi Jet Fusion technology.

Why Classic?

- Balance – optimal balance of cost efficiency and reproducible part quality.

- Process reliability – proven parameters trusted by series manufacturers.

- Wide range of applications – recommended for function-critical components in systems, vehicles, devices, and more.

This positions PA 12 | Classic right between the particularly cost-effective Essential variant and the high-performance Performance version – the smart choice for economical series production without compromising on quality.

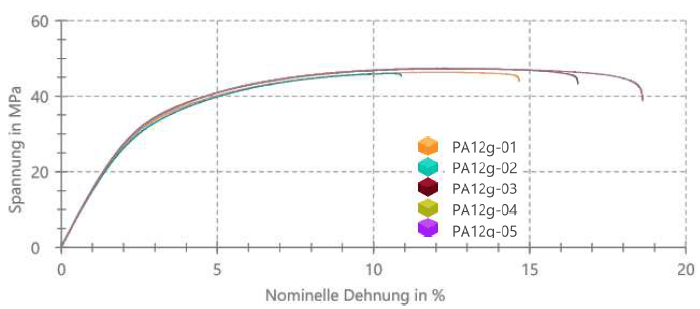

Material properties of PA 12 | Classic

Mechanical Properties

Polyamide 12 | Classic is a strong, highly durable, and long-lasting plastic. The material properties are largely isotropic (same mechanical values in all orientations). The thinner the wall thickness, the higher the flexibility, especially at wall thicknesses of 1 mm or less.

- Tensile strength: ~ 48 ± 5 MPa

- Elongation at break: 13 ± 6 %

- Young’s modulus: 1,500 ± 200 MPa

- Density: ~0.9 – 1.0 g /cm³ (geometry-dependent)

Thermal Properties

For continuous loads, 95 °C should not be exceeded. For short-term loads, up to max. 120 °C are possible depending on geometry. In particular, with thin wall thicknesses (< 2 mm) and/or simultaneous mechanical stress, the load capacity is reduced.

- Heat deflection temperature (HDT) at 0.45 MPa: 175 °C

- Heat deflection temperature (HDT) at 1.82 MPa: 95 °C

Surface Properties

The raw material Polyamide 12 processed in Multi Jet Fusion is in powder form. This results in a slightly rough surface, similar to fine sandpaper. The stair-step effects typical of 3D printing (print lines) are visible at shallow angles (up to approx. 15°) and are quite fine, since the layer thickness is only 80 µm.

- Roughness Ra underside: 5 ± 2 µm

- Roughness Ra topside: 10 ± 2 µm

- Roughness Ra slope (45°): 8 ± 2 µm

Color

In the 3D printing process (more details on Multi Jet Fusion), the white PA 12 powder is given a black color. The components are therefore completely black inside. On the surface, a white fraction remains, consisting partly of sintered white powder particles. This results in the typical gray production color. Due to technical reasons, this is rather inhomogeneous with light and dark areas.

Optionally, a black dyeing process is possible, in which the remaining white fraction is pigmented. The result is homogeneous, completely black components (i.e., also black inside).

Downloads

- Material data sheet: Material Data Sheet PA 12

- RoHS/Reach: RoHS/REACH Certificate

- Flammability: UL 94 and UL 746A Certification

- UV stability: Accelerated Weathering Test

- Chemical resistance: Chemical Compatibility with Automotive Fluids

- Overview of regulatory requirements: Summary of Regulatory Compliance and Environmental Attributes

- Biocompatibility: USP Class I-VI and FDA Intact Skin Surface Devices Certification

- Application for toys: Statement of Composition for Toy Applications

Manufacturing tolerance

The general tolerance for Polyamide 12 | Classic is ± 0.3 mm up to 100 mm outer dimension, above that ± 0.3%. For large-area, flat geometries, warpage may also occur.

Post-processing of PA 12 | Classic

Black dyeing & Shot Peening

Recommended for visible parts: Dyeing followed by surface densification for a visually and haptically high-quality surface

Order notes

- Lead time: + 1 working day

- Price: Depending on quantity and size, typical unit costs of approx. EUR 1 – EUR 10 excl. VAT

- Maximum size: 350 x 250 x 150 mm

Find more information on our dyeing page. Colored dyes are available with white PA 12 | White.

Vapor Smoothing (Chemical Smoothing)

Chemical surface finishing, in which a pore-free surface with reduced roughness is created. Key applications are liquid- or gas-carrying components, parts where easy cleaning is required (medical, clean room), or as a basis for subsequent coating processes (reducing “outgassing”, reducing porosity, smoothing).

Order notes

- Lead time: + 3 working days

- Price: Depending on quantity and size, typical unit costs of approx. EUR 5 – EUR 10 excl. VAT

More information can be found on our Chemical Smoothing page.

Painting

In wet painting, a coating specifically formulated for Polyamide 12 is applied.

Order notes

- Lead time: + approx. 2 weeks

- Price: Highly dependent on size and quantity. Note: The minimum order value for processing is EUR 100 excl. VAT.

Learn more on our Painting page.

Design guidelines

A brief overview of the most important rules for designing your additively manufactured parts. More detailed information and tutorials on design for 3D printing can be found here.

Minimum wall thickness

The minimum wall thickness should not be less than 0.7 mm. For longer objects/surfaces or for objects exposed to mechanical stress, you should increase the wall thickness.

Hollow spaces

Hollowed objects can be printed, but openings (min. 10 mm diameter) must be inserted so that excess material can be removed. For larger hollow spaces, you should plan several openings. The raw material is compacted during the printing process, therefore excess material is very difficult to remove.

Clearances

Maintain a clearance of min. 0.5 mm for grooves or closely adjacent walls. Individual objects (“shells”) must always be uploaded as separate files unless they are firmly connected to each other.

Resolution

Details down to a size of approx. 0.5 mm can be represented.

Interlocked objects

Interlocked objects can be printed. Please observe the minimum clearance between the objects of at least 0.5 mm. Also make sure that the corresponding areas are accessible in order to remove excess material powder.

Size

The object should not exceed 370 x 274 x 380 mm.

Prices

Quotation

You can receive an instant price quote for your model in our online 3D printing service.

Calculation

Prices are calculated depending, among other things, on machine volume, model surface, and material usage.

Express/Priority surcharge approx. 25 %

Minimum order value

EUR 50,- plus VAT (EUR 59.50 incl. VAT) / order

Discounts

For larger quantities, a significant reduction compared to the standard price is possible, depending on quantity, part size, and geometry.