3Faktur carries out extensive quality checks on every production run to guarantee the highest possible level of quality that can be replicated. You can order individual (e.g. company or industry-specific) test reports or standard documents. Standard reports can be ordered via our online 3D printing service, for individual formats please contact our customer service team.

Standard Protocols

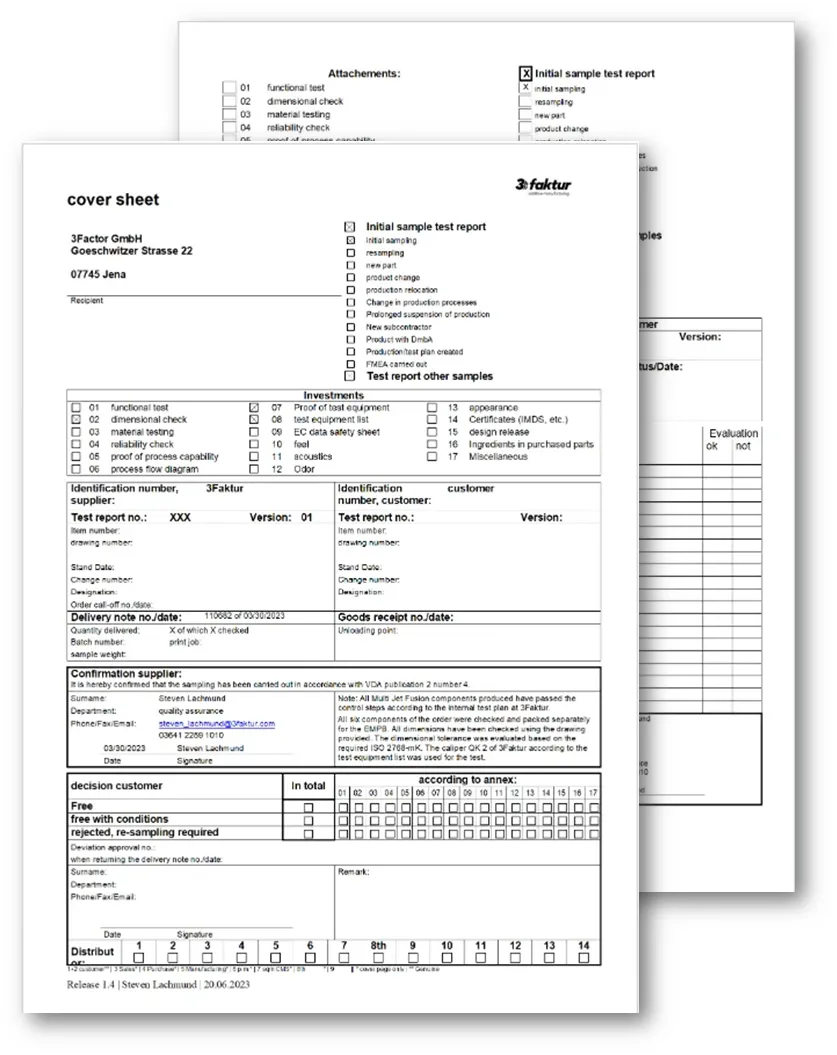

Initial Sample Test Report (ISIR)

The initial sample test report (ISIR) serves as documented confirmation of the capability for series production and the consistency of the quality of additively manufactured parts. This is achieved by using a previously agreed number of units from the manufactured production series for initial sampling. Initial samples are products that have been produced for the first time under real and standardized conditions. All subsequent production runs and the release of such products will take place under identical conditions, based on the initial sample.

Scope of services

When ordering an ISIR, please provide the size of the batch to be inspected (3 will be inspected as a minimum if available), together with the number of measuring points to be inspected (also 3 as standard) and a technical drawing showing these measuring points.

Influence on the delivery time

1 to a few working days delay, depending on the scope of testing.

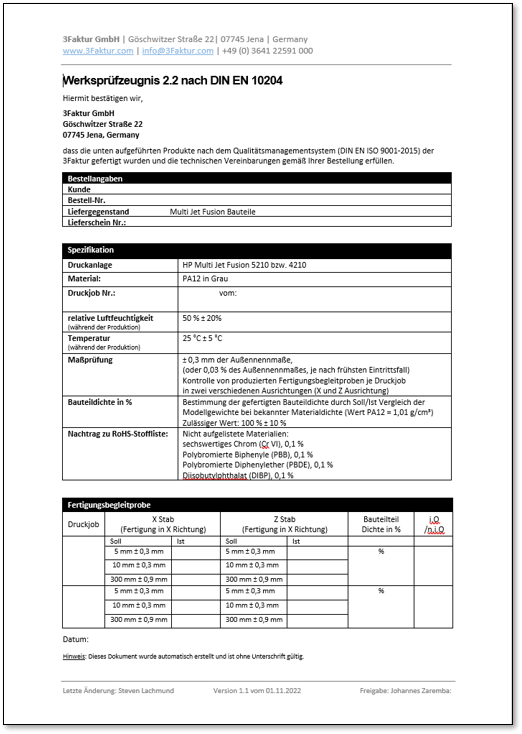

Certificate of Compliance (Test Certificate 2.2)

A factory certificate, also known as test certificate 2.2, documents that the additively manufactured components meet the specifications defined during production. This certificate confirms the conformity of the produced items with the specified criteria, based on general or indirect measurements taken during the production process. The issue of a factory certificate confirms that production was carried out under standardized and documented conditions.

Scope of services

Issue of an electronic report with process parameters and non-specific test results.

Influence on the delivery time

None. Dispatch of the report usually 1 – 2 working days after dispatch

Acceptance Test Certificate (Test Certificate 3.1)

An acceptance test certificate, also known as test certificate 3.1, documents that the additively manufactured components meet the specifications defined during production. This certificate confirms the conformity of the produced items with the specified criteria, based on specific measurements and tests carried out as part of the production process. In contrast to the inspection certificate 2.2, the acceptance test certificate provides a more detailed inspection and contains specific data on the properties of the product. By issuing an inspection certificate, the quality of the product is certified under standardized and documented conditions.

Scope of services

At least 3 components are tested at 3 measuring points each. The desired number of components and measuring points to be measured can be specified in the ordering system.

Influence on the delivery time

1 to a few working days delay, depending on the scope of testing.