Polyamide 12 (PA 12) is a technically advanced, rigid plastic specifically developed for additive series production. The thermoplastic material convinces with high mechanical strength, thermal stability, chemical resistance, and low unit costs – ideal for functional parts in industrial use. We process the material in various options using the Multi Jet Fusion process.

Quick Facts

Technology

Multi Jet Fusion

Colors

gray, black;

white, multicolor (only PA 12 | White)

Build Volume

380 x 284 x 380 mm

Production Time

3 working days (Prio)

6 WD (Standard)

12 WD (Flex)

Accuracy

± 0.3 %

(min. ± 0.3 mm)

1. Our PA 12 Options

By using different raw materials and production-specific parameters, a wide range of properties is created – from particularly economical to high-strength or visually refined. For every requirement, you will find the right PA 12 variant with us.

PA 12 | Classic

Our industry-leading standard since 2017:

The established PA 12 solution: consistent material quality and high process reliability – ideal for series production and long-running projects.

More information

APPLICATION

Universal option for (almost) all components in visible and non-visible areas.

COST

$$$$$

STRENGTH

★ ★ ★ ★ ☆

SURFACE

★ ★ ★ ★ ☆

PA 12 | Essential

Our most economical option: Essential offers a robust balance between cost and quality – the ideal choice for functional prototypes and cost-efficient small series.

More information

APPLICATION

Rather compact components with a focus on cost-efficiency.

COST

$$$$

STRENGTH

★ ★ ★ ☆ ☆

SURFACE

★ ★ ★ ☆ ☆

PA 12 | Smooth

Our best surface finish: Thanks to an especially fine raw material, a smooth and homogeneous feel is achieved – ideal for visible components in housings, devices, or control elements where appearance matters.

More information

APPLICATION

Visible parts, including bulky ones, such as housings.

COST

$$$$

STRENGTH

★★ ★ ☆ ☆

SURFACE

★★★★ ☆

PA 12 | Performance

Our most powerful option: Optimized material and printing parameters ensure maximum durability and dimensional stability – recommended for stressed functional parts.

More information

APPLICATION

Parts with increased requirements for mechanical load.

COST

$$$$

STRENGTH

★★★★ ★

SURFACE

★★★★★ ☆

PA 12 | White

Our widest color range: “PA 12 W” has a white base color and can be dyed in various colors. This makes it the ideal material for visible parts with color requirements or components in industrial signal colors.

More information

APPLICATION

Visible components with color requirements.

COST

$$$$$

STRENGTH

★★★ ★ ☆

SURFACE

★★★★ ☆

PA 12 | FR

Our flame-retardant option: “PA 12 FR” is a flame-retardant version of PA 12 and meets the UL 94 V0 classification from 2.5 mm wall thickness. It is suitable for applications with increased safety requirements, particularly in electrical and transportation environments.

More information

APPLICATION

Components with flame-retardancy requirements.

COST

$$$$

STRENGTH

★★★ ☆ ☆

SURFACE

★★★★ ☆

2. PA 12 Variants in Detailed Comparison

2.1. General Variants

PA 12 | Classic

Our standard for proven series quality.

MANUFACTURER / PRODUCT

Evonik / HP 3D HR PA 12

COLORS

Gray, Black

LAYER THICKNESS

80 µm

PRINT MODE

Balanced

SYSTEM

HP MJF 5210

GENERAL TOLERANCE

±0.30 mm or ±0.3%

PRODUCTION TIME

Prio: from 3 WD

Standard: from 6 WD

Flex: from 12 WD

PA 12 | Essential

Best cost-efficiency without sacrificing industrial usability.

MANUFACTURER / PRODUCT

Evonik / HP 3D HR PA 12

COLORS

Gray, Black

LAYER THICKNESS

120 µm

PRINT MODE

Fast

SYSTEM

HP MJF 5210

GENERAL TOLERANCE

±0.3 mm or ±0.3%

PRODUCTION TIME

Prio: from 3 WD

Standard: from 6 WD

Flex: from 12 WD

PA 12 | Performance

Maximum mechanical performance for high technical requirements.

MANUFACTURER / PRODUCT

Evonik / HP 3D HR PA 12

COLORS

Gray, Black

LAYER THICKNESS

90 µm

PRINT MODE

Robust (“Balanced 56”)

SYSTEM

HP MJF 5620

GENERAL TOLERANCE

±0.3 mm or ±0.3%

PRODUCTION TIME

–

Standard: from 6 WD

Flex: from 12 WD

PA 12 | Smooth

Finest surface for visible parts.

MANUFACTURER / PRODUCT

Arkema / HP 3D HR PA 12 S

COLORS

Gray, Black

LAYER THICKNESS

80 µm

PRINT MODE

Custom

SYSTEM

HP MJF 5620

GENERAL TOLERANCE

±0.3 mm or ±0.3%

PRODUCTION TIME

Prio: from 3 WD

Standard: from 6 WD

Flex: from 12 WD

2.2. Variants with Special Properties

PA 12 | White

More color variety for visible parts.

MANUFACTURER / PRODUCT

Evonik / HP 3D HR PA 12 W

COLORS

White, Colored

LAYER THICKNESS

80 µm

PRINT MODE

Balanced

SYSTEM

HP MJF 5420

GENERAL TOLERANCE

±0.3 mm or ±0.3%

PRODUCTION TIME

Prio: –

Standard: from 7 WD

Flex: –

PA 12 | FR

For maximum safety: flame-retardant, certified, industry-proven.

MANUFACTURER / PRODUCT

Evonik / HP 3D HR PA 12 FR

COLORS

Gray

LAYER THICKNESS

90 µm

PRINT MODE

Balanced

SYSTEM

HP MJF 5620

GENERAL TOLERANCE

±0.3 mm or ±0.3%

PRODUCTION TIME

Prio: –

Standard: from 10 WD

Flex: –

3. Polyamide 12: One Polymer, Numerous Applications

Polyamide 12 (PA 12) stands for durability, high load capacity, as well as exceptional thermal and chemical stability. These properties make the material the first choice for demanding applications in:

- Industry & High-Tech

- Medical Technology

- Automotive & Vehicle Construction

- Electronics

- Optics

- Consumer Goods

Thanks to state-of-the-art manufacturing processes, 3D-printed PA 12 components – depending on the process option – achieve almost the same mechanical and functional properties as injection-molded components.

Mechanical Parts

PA 12 is flexible when thin-walled, rigid when thick-walled, abrasion-resistant – ideal for gears, connectors, propellers, and more.

Recommended variants: PA 12 | Performance or Classic, optionally combined with chemical smoothing for thin, dynamically loaded, or friction-intensive parts.

Structural Components

PA 12 enables freely designable, resource-efficient mounts – from circuit board to motor brackets – highly optimized with minimal material usage.

Recommended variants: PA 12 | Essential

Tools & Fixtures

The production method enables fast manufacturing of complex fixtures. The material is, among others, oil-resistant and can withstand both thermal and mechanical stress.

Recommended variants: PA 12 | Performance (for dynamic load or thin walls), Essential or Classic.

Gas-Conducting Systems

PA 12 allows the production of complex internal channels and integrated connectors in a single print job – without assembly. For absolutely leak-proof channels, we work with you to ensure the design-dependent minimum channel diameter.

Recommended variants: PA 12 | Classic or Essential combined with Chemical Smoothing.

Orthoses

PA 12 enables patient-specific shapes, is skin-friendly and extremely durable – perfect for long-lasting orthoses. For flexible areas, we additionally recommend elastic TPU.

Recommended variants: PA 12 | Classic, Smooth, White or Performance, depending on the application.

4. Polyamide 12: Finishing & Post-Processing

Coloring

- Standard Dyeing Black: for all variants except PA 12 | White

- DeepDye Dyeing Black: for all variants except “White”

- DeepDye Dyeing Colored: for PA 12 | White

Note: According to Bluecard, no additional finishing steps are permitted for PA 12 | FR.

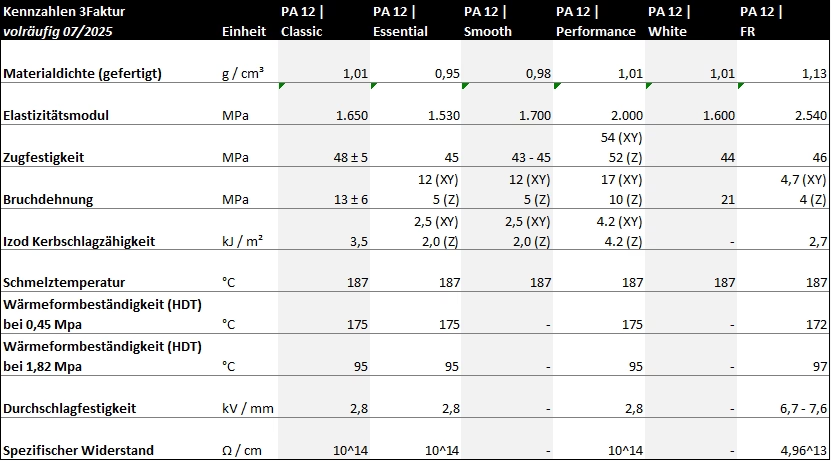

5. Polyamide 12: Mechanical, Thermal and Electrical Key Figures

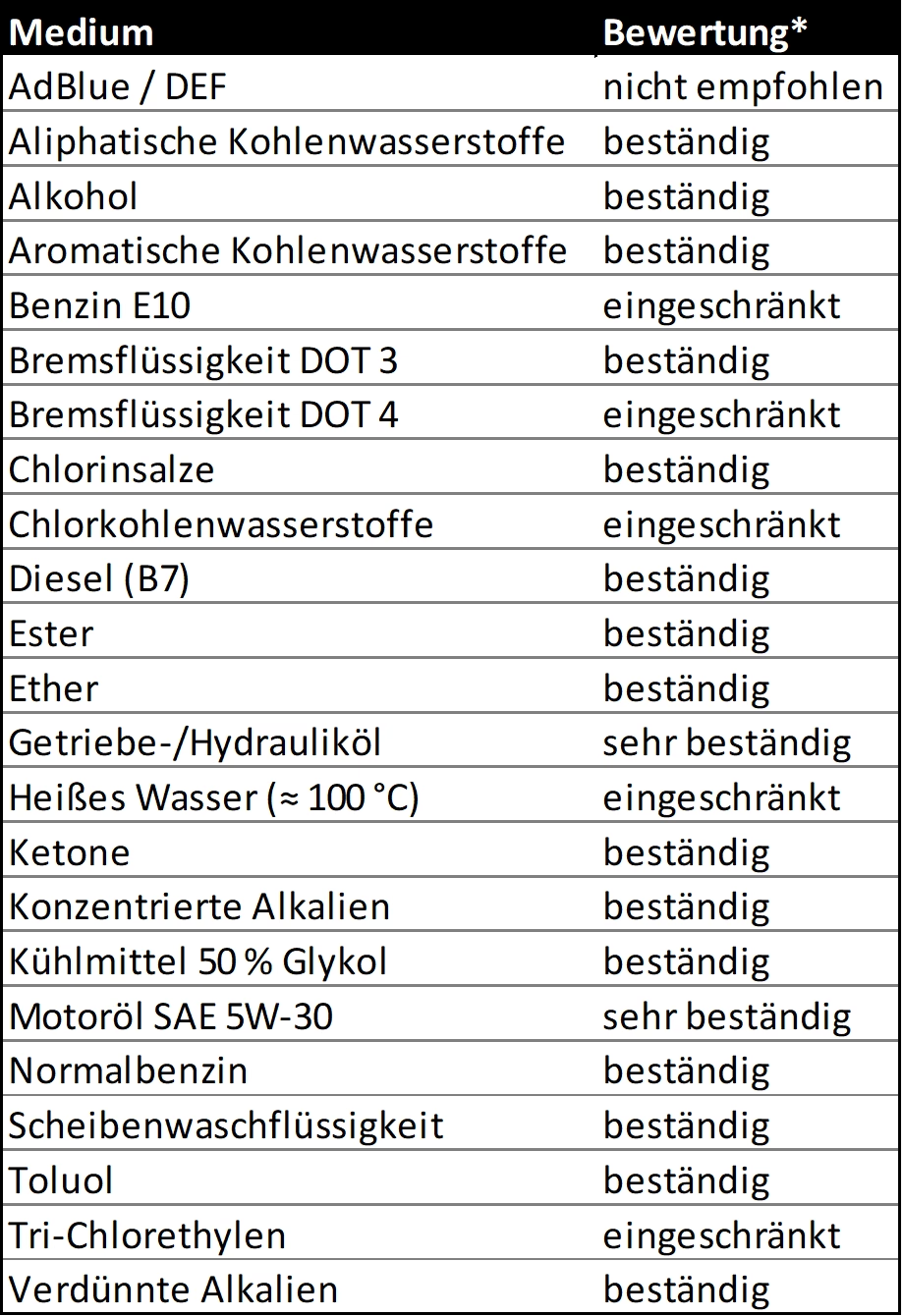

6. Polyamide 12: Chemical Resistance

HP Multi Jet Fusion PA 12 is characterized by exceptionally high resistance to non-polar media. Engine, transmission and hydraulic oils, diesel as well as common coolants and windshield washer fluids hardly affect the material even under continuous exposure – dimensional stability and mechanical properties remain almost unchanged.

With strongly polar liquids, e.g. brake fluid (DOT 4), PA 12 absorbs a small amount of mass and loses strength. For critical sealing areas, we recommend thin barrier coatings or constructive safety margins.

PA 12 | White is also sterilization-resistant: steam, EtO, gamma and e-beam cycles cause only minimal changes (< 10% strength loss, ΔE < 2). This makes PA 12 ideal for reprocessable medical devices and functional parts in the food & life science sector.

Polyamide 12 therefore offers a wide range of applications – from heavily loaded automotive components to fluid handling systems to medical devices.

* Notes on interpretation

- Resistant = < 5% property change or manufacturer rating “Good”.

- Limited = 5–15% property change or “Moderate” → application possible, but protection via coating or safety margin recommended.

- Not recommended = > 15% property change or significantly impaired mechanics.

7. Polyamide 12: UV Stability

Although PA 12 is overall a very robust material, prolonged UV exposure also leads to aging effects here. The following table gives you a compact overview of the UV resistance of the individual PA 12 variants.

HP HR PA 12 enabled by Evonik

PA 12 | Classic

PA 12 | Essential

PA 12 | Performance

UV Resistance

Good: The base polyamide withstands short-term radiation, but ages visibly under permanent outdoor exposure (discoloration, embrittlement).

Practical Notes

For permanent outdoor use, provide black coloring or clear coat/PU coating.

HP HR PA 12 W enabled by Evonik

PA 12 | White

UV Resistance

Very Good: The white powder contains a light-stable additive package that protects the material against yellowing for a long time.

Practical Notes

With long-term exposure, yellowing may eventually occur, which can be reduced by coloring or coating.

HP HR PA 12 S enabled by Arkema

PA 12 | Smooth

UV Resistance

Very Good: PA 12 S is based on a specially modified PA 12 system with UV additive.

Practical Notes

The material is ideal for continuous outdoor use. Here too, at least black coloring is recommended.

8. Polyamide 12: Design Guidelines

Wall Thicknesses

Minimum Wall Thicknesses

- PA 12 | Classic, PA 12 | Performance, PA 12 | White: 0.7 mm

- PA 12 | Essential; PA 12 | Smooth: 1.0 mm

For free-standing walls or extrusions as well as for larger surfaces, the wall thickness should be increased accordingly.

Maximum Wall Thicknesses

From approx. 6 mm wall thickness, we insert a lattice structure into models before printing. For some variants (Classic, Performance, White) you can opt out of this. More info on lattice structures can be found here.

Size

Maximum Size

The maximum size for all variants is 370 x 274 x 380 mm.

Minimum Size

The detail resolution of very small parts is limited. We recommend that at least one dimension of the part exceeds 10 mm.

Clearances

Maintain a minimum clearance of 0.5 mm between two walls (applies to all variants).

Individual objects (“shells”) must always be uploaded as separate files if they are not firmly connected.

Resolution

Details down to a size of approx. 0.5 mm (guideline value) can be displayed.

Variants with better surface quality, especially PA 12 | Smooth, can also be slightly smaller, whereas PA 12 | Essential has reduced resolution.

Interlocking Objects

Interlocking objects can be printed in all variants.

Please note the minimum clearance between objects of 0.5 mm and ensure that the corresponding areas are accessible to remove excess material powder.

Hollow Parts

Hollow objects can be printed in all variants, but openings (min. 10 mm diameter) must be added so that excess material can be removed.

For larger cavities, you should plan several openings. The raw material is highly compacted during the printing process, so removing excess material is very difficult.

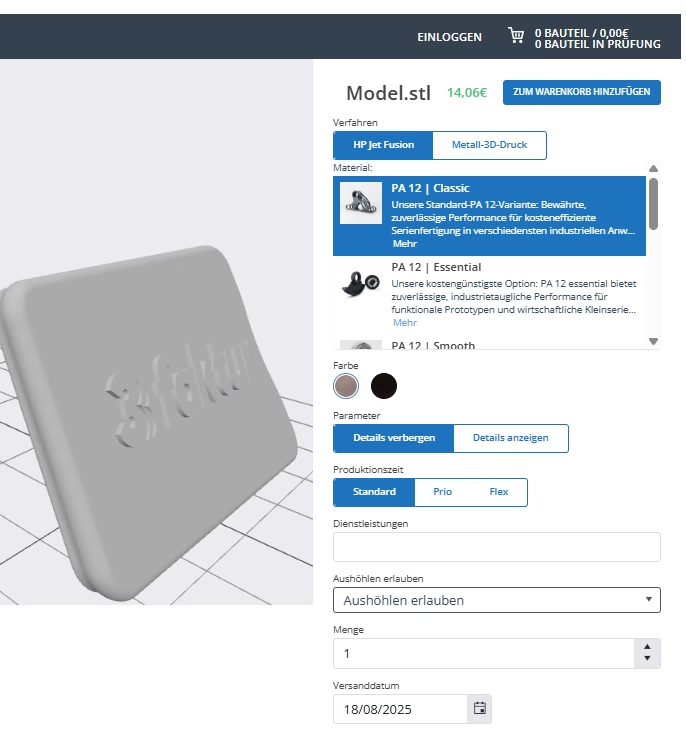

9. Your Quote at 3Faktur

Upload your 3D data in STEP or STL format – our online tool automatically analyzes it and generates your individual instant quote within seconds.

Need advice for your project? Our customer service will be happy to advise you.