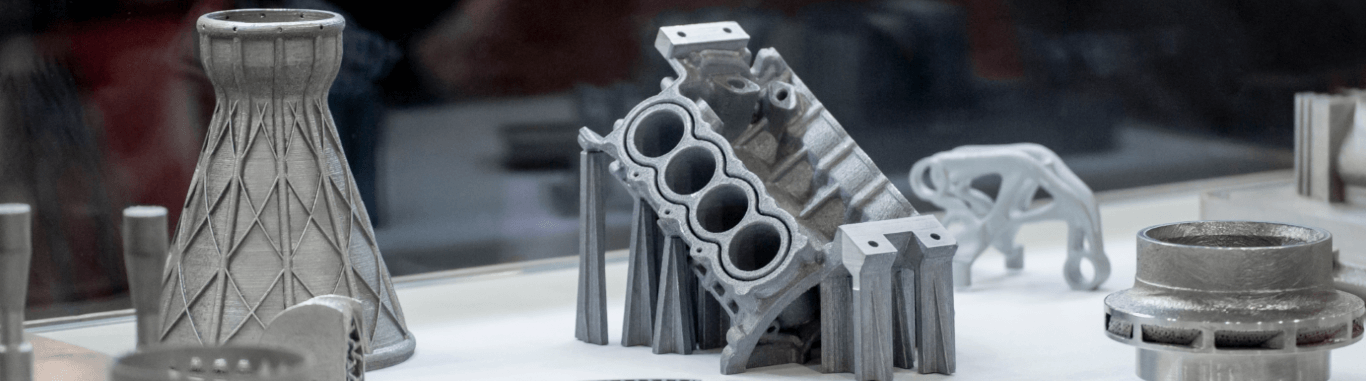

1.4404, also known as stainless steel 316L, is a high-performance alloy characterized by its excellent corrosion resistance and strength. This alloy primarily consists of iron, chromium, nickel, and molybdenum, giving it superior mechanical properties. 316L offers high resistance to corrosive environments and is particularly resistant to pitting and intergranular corrosion.

With its high strength and ductility, 316L is ideal for applications in medical technology, the chemical industry, the food and beverage industry, and the maritime sector. The alloy enables the production of precise and complex geometries, rapid prototyping processes, and efficient material utilization, making it a preferred choice in additive manufacturing. 316L is also easy to weld and process, facilitating the production of customized and durable components.

Quick Info

Technology

Metal 3D Printing

Colors

–

Build Volume

150 x 150 x 150 mm

Production Time

approx. 10 working days

Accuracy

ISO 2678-1-m

Material Properties of Stainless Steel 316L

Additively manufactured 316L, also known as stainless steel 1.4404, is characterized by several remarkable material properties that make it ideal for a wide range of applications:

- Excellent Corrosion Resistance: 316L is particularly resistant to corrosion in aggressive environments, including chloride-containing and acidic media; especially suitable for applications requiring high resistance to chemical attacks.

- High Strength and Ductility: The alloy offers a good combination of strength and flexibility. It can withstand heavy loads while also adapting to different shapes and designs.

- Biocompatibility: 316L is biocompatible, making it ideal for medical applications, including implants and surgical instruments.

- Processing Properties: 316L is easy to weld and process, facilitating the production and post-processing of components.

These properties make additively manufactured 316L a versatile material widely used in industries such as chemical processing, food processing, medicine, and maritime applications.

- Tensile Strength: 599 ± 20 MPa

- 0.2% Yield Strength: 491 ± 22 MPa

- Elongation at Break: 43.8 ± 4.5%

- Modulus of Elasticity: 169 ± 17 MPa

- Density: ~7.9 g/cm³

Downloads

- Material Data Sheet: Data Sheet 316L

Manufacturing Tolerance

The general tolerance follows ISO 2678-1-m.

Post-Processing

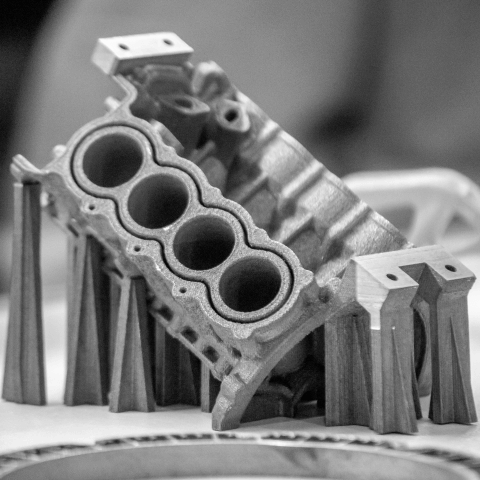

Standard: Removing Support Structures & Blasting

For all manufactured components, the support structures are removed. These are first roughly removed and then manually ground. The contact points on the component are therefore visually noticeable.

Subsequently, the components are blasted with glass beads, improving the homogeneity of the surface as well as the feel.

Optional: Additional Options

The post-processing options are diverse and can be optionally arranged with us. Examples include machining to achieve defined tolerances or surface roughness, heat treatment (e.g., stress relief annealing), or surface treatments such as vibratory finishing.

Design Guidelines

Minimal Wall Thicknesses

The minimum wall thickness should be no less than 0.5 mm. For longer objects/surfaces or for objects subjected to mechanical loads, you should increase the wall thickness. In theory, wall thicknesses down to 0.3 mm are possible, but these can be damaged during post-processing (e.g., cleaning blasting). Therefore, production in such cases is at your own risk.

Hollow Spaces

Hollow objects can be printed. However, openings (min. 2 mm in diameter) must be included to allow excess material to be removed. For larger or branched hollow spaces, you should plan for several openings.

Gaps

Maintain a gap of at least 0.3 mm for grooves or walls that are close together. Separate objects (“shells”) must always be uploaded as their own file unless they are firmly connected.

Resolution

Details up to a size of about 0.3 mm can be represented.

Interlocking Objects

Unfortunately, interlocking objects cannot be manufactured in powder-bed-based 3D printing.

Size

The object should not be larger than 150 x 150 x 150 mm. Larger components will be reviewed upon request.

Applications

Tools & Fixtures

Due to the optimal ratio of formability to strength, 316L is the ideal material for use in fixture construction and tool manufacturing.

Prototypes

316L is particularly well-suited for prototypes. It has excellent corrosion resistance and high strength, enabling precise and durable parts. The alloy is easy to weld and process, facilitating quick adjustments and iterations. Additionally, 316L allows for the production of complex geometries, offering more flexibility in prototyping.

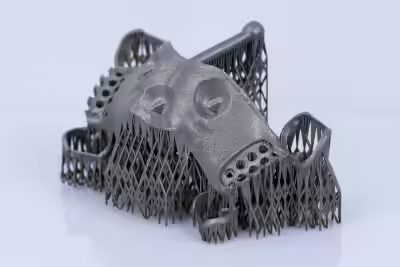

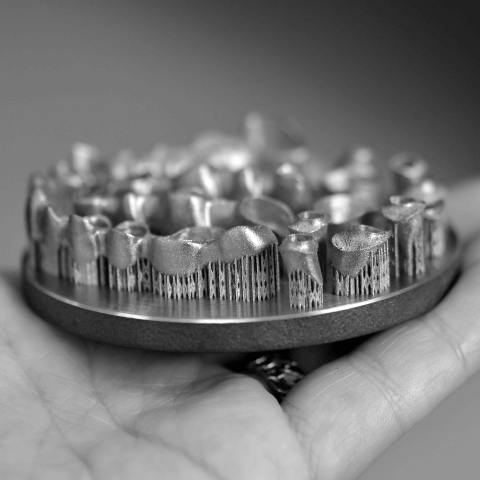

Medical Instruments

Additively manufactured 316L is ideal for medical components, offering excellent corrosion resistance and biocompatibility. This alloy enables the production of durable and safe parts that meet the stringent requirements of the medical field. Through 3D printing, highly precise and custom structures can be produced, tailored specifically to the individual needs of patients, enhancing the efficiency and functionality of medical devices and implants.

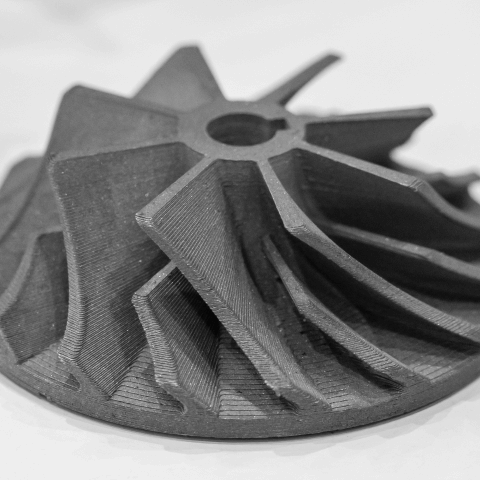

Elements for Chemical Reactors

Due to its excellent resistance to aggressive chemicals and high temperatures, stainless steel 316L is particularly suitable for components in chemical reactors. The alloy ensures long-lasting and robust parts that operate reliably even under extreme conditions. Through 3D printing, highly complex and precise structures can be manufactured, specifically tailored to the requirements of chemical processes, significantly improving the efficiency and performance of the reactors.

Components for Food Processing Equipment

316L is excellently suited for use in food processing as it has high resistance to corrosive food acids and cleaning agents. The alloy combines strength with the ability to produce hygienic and durable parts. 3D printing also allows for the production of precise and complex geometries, which are essential for custom and efficient components in the food industry.

Maritime Components

Additively manufactured 316L is ideal for maritime components. It has excellent corrosion resistance to saltwater and other corrosive environments. The high strength and ductility of the alloy ensure the durability and reliability of the manufactured parts under extreme conditions. Additionally, 3D printing with 316L allows for the production of complex and precise geometries that are advantageous in maritime applications such as pumps, valves, and fasteners.

Prices

Offer

An instant price quote for metal 3D printing is currently not possible due to the complexity of the technology. Please use our manual inquiry function for your request. Your inquiries will be answered within one working day.

Calculation

The prices are mainly based on machine running times and the effort required for post-processing.

Minimum Order Value

EUR 50,- excl. VAT (EUR 59.50 incl. VAT) / order

Discounts

For larger quantities, a reduction compared to the standard price is possible, depending on the quantity, part size, and geometry.