Information about our 3D printing service

Here you will find a brief summary of our offerings, as well as information about the ordering process and technical information for configuration in our online calculator. More detailed information is available on the respective detail pages.

Table of Contents

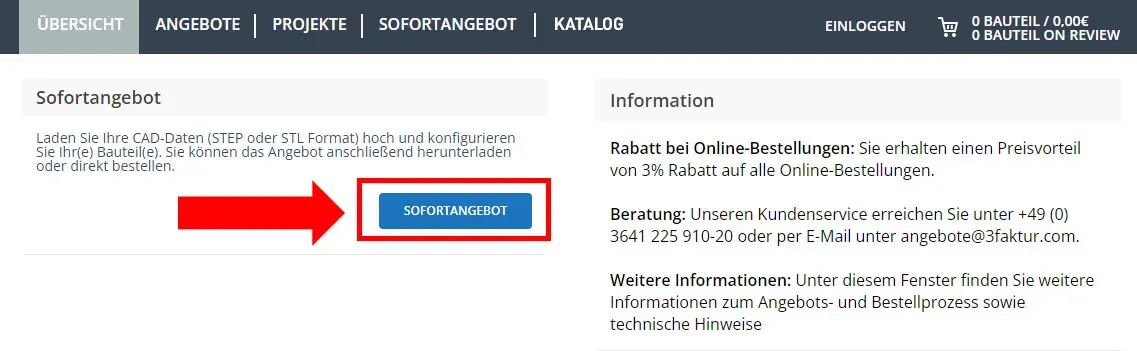

1) Ordering Process

A detailed guide to the ordering process can be found here: Offer & Ordering Process.

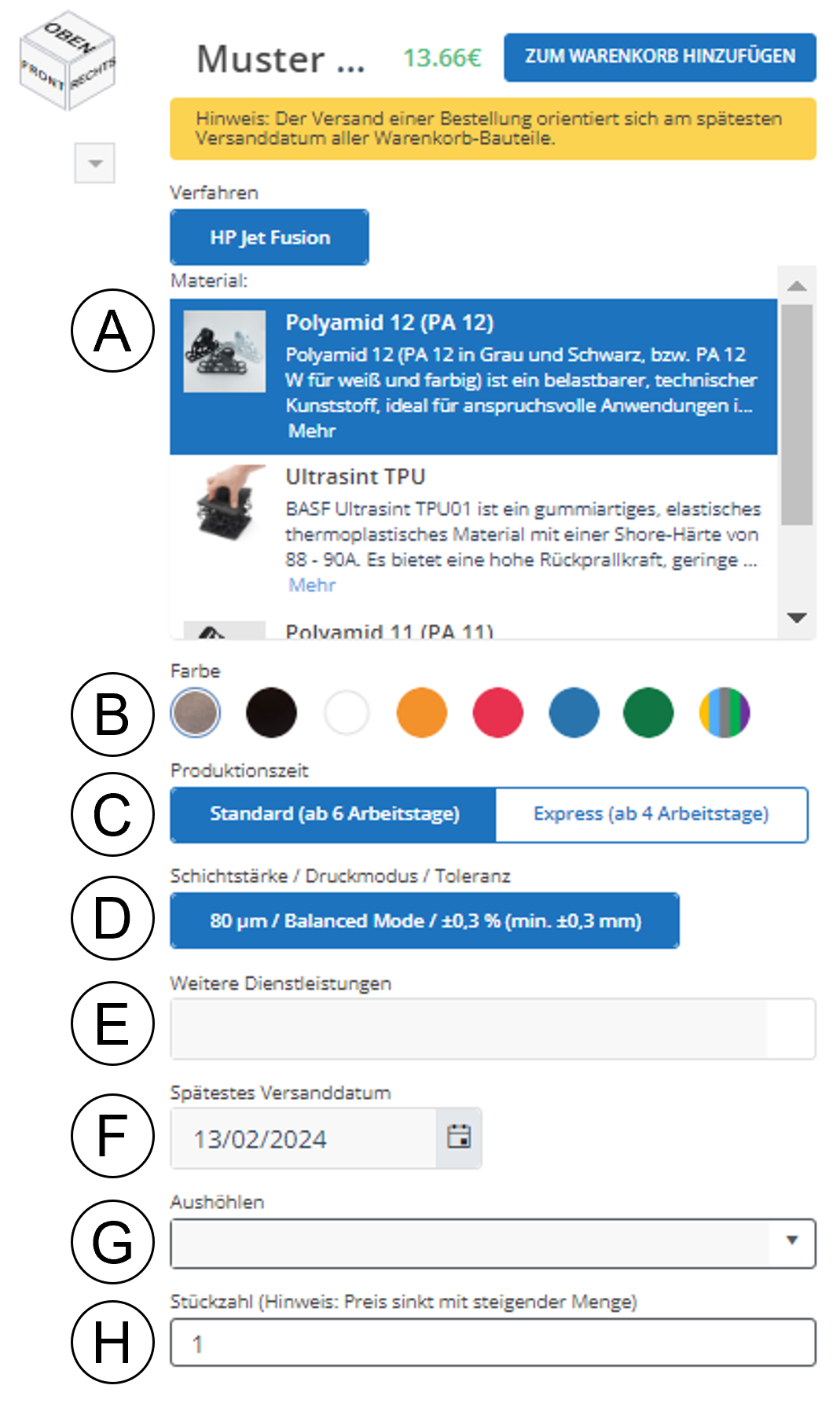

Step 2: Configuration

Configure material, color, production time, quantity, and optionally additional services like surface finishing etc.

Step 3: Optional: Download Quote

After adding the part or parts to the list, you can download your offer as a PDF. To do this, go to the cart (list) and click on the small printer icon at the bottom right next to the “Checkout” button. This process requires a login to your account.

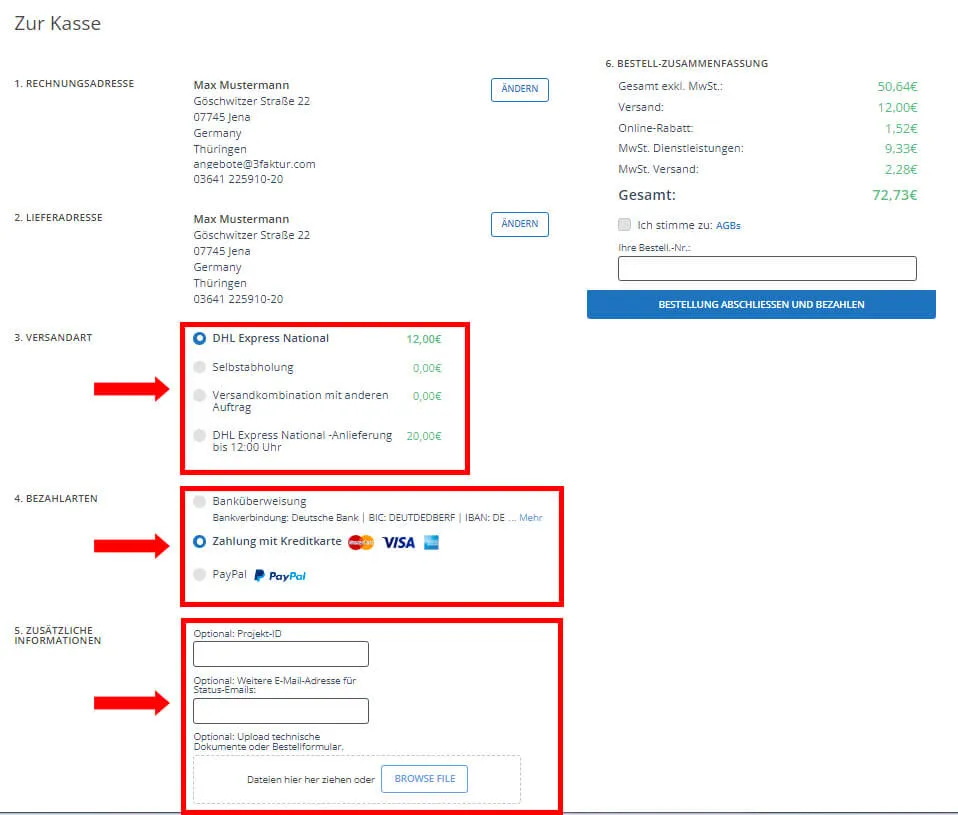

Step 4: Check-Out

By clicking on “Checkout,” you will be taken to the check-out page. There you enter your data (billing and delivery address), choose a payment method, confirm the General Terms and Conditions and Privacy Policy, and confirm your order.

2) Materials & Color

2a) Material

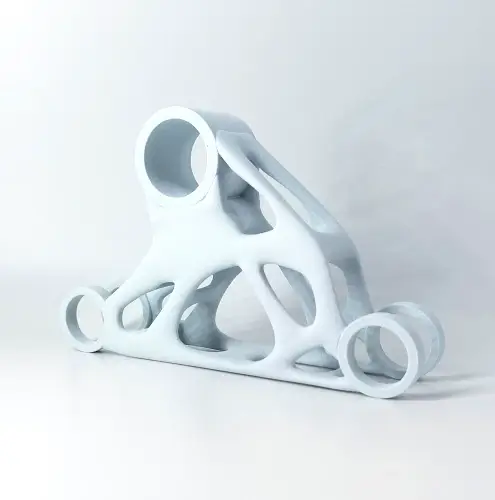

More information about our materials for our 3D printing service can be found on the page Overview of Materials. All materials are produced using the powder bed 3D printing process Multi Jet Fusion.

Polyamide 12 (PA 12 & PA 12 W)

Polyamide 12 is a very high-performance “all-rounder” plastic suitable for a wide range of industrial applications. The material is available as PA 12 in gray and PA 12 W in white base color. The specifications of both are comparable.

BASF UltrasintTM TPU01

BASF Ultrasint TPU is an elastic plastic with a Shore hardness of 88 – 90A. The material is used for damping, in handles, seals, orthoses, grippers, or heavily stressed casings and covers.

Polyamide 11

PA 11, made from renewable sources, surpasses PA 12 in flexibility and impact resistance. The material is characterized by toughness and is ideally suited for film hinges, snap connections, and robust orthoses.

2b) Colors

Gray

Gray is the production color and is due to a remaining white component on otherwise black parts. The gray is technically caused and therefore not recommended for visible surfaces.

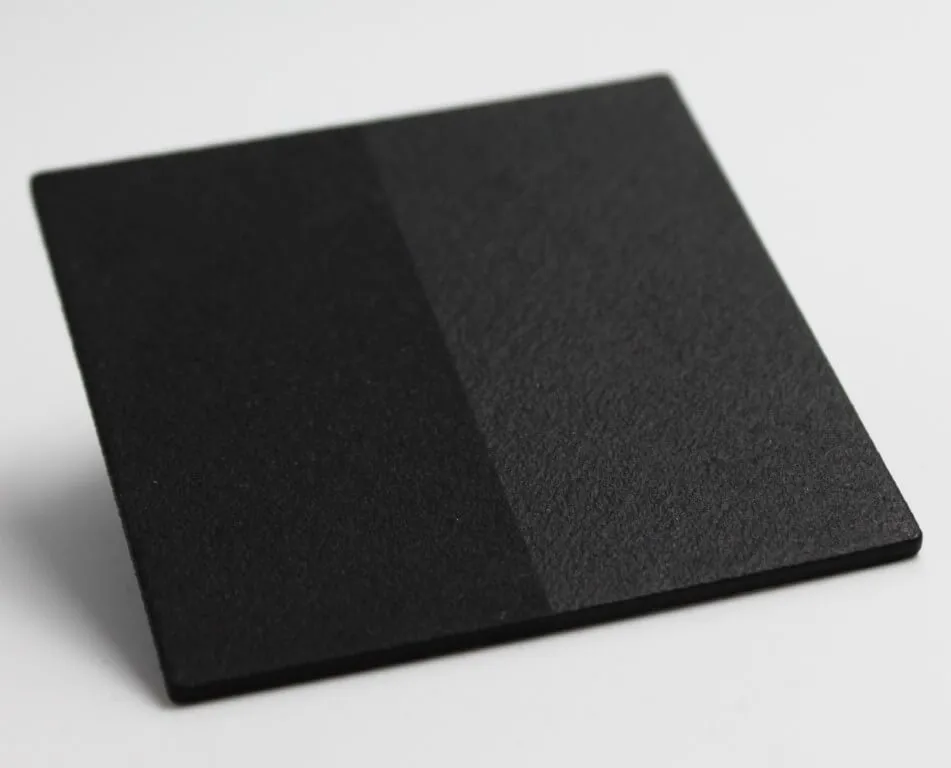

Black

The white component remaining on the surface is blackened through a dyeing process. It involves a pigmentation; no layer is applied.

White

Components made of PA 12 W (configured under PA 12 and color White) have specifications similar to the gray material. The white has a slight blue tint and is very resistant to UV exposure.

Colorful

For colorful colors, PA 12 W (White) is dyed using Dyemansion DeepDye Coloring. Standard colors are dyed more frequently and have a lower minimum order requirement. Special colors are dyed at the customer’s request, hence the higher minimum order. In the latter case, you can select the desired color from the drop-down menu.

3) Production Time & Shipping Date

The standard time indicates the normal turnaround time from order to shipping in our 3D printing bureau. Express production times are available for some materials or combinations. For both options, standard and express, the deadline is 12:00 PM; for orders placed after 12:00 PM, the specified production time starts the following day.

The shipping date calculates the expected shipping date based on the selected production time. For orders with multiple items and shipping dates, the latest date applies.

4) Layer Thickness / Printing Mode / Tolerance

The specifications refer to general information about the printing process and tolerance.

- Layer Thickness: Specifies the height of a layer in the Z-direction. This varies depending on the material and printing mode.

- Printing Mode: We print in the quality-oriented “Balanced Mode”.

- Tolerance: Specifies the general tolerance for the respective material.

5) Additional Services

5a) Surface Finishing

Chemical Smoothing

This process uses a vaporized solvent to smooth and seal the surface. You can choose the support surface for the process – detailed information can be found here.

More on chemical smoothing (“Vapor Smoothing”).

Shot Peening

Shot Peening is included in the price for all colored components and does not need to be ordered separately. More on Shot Peening.

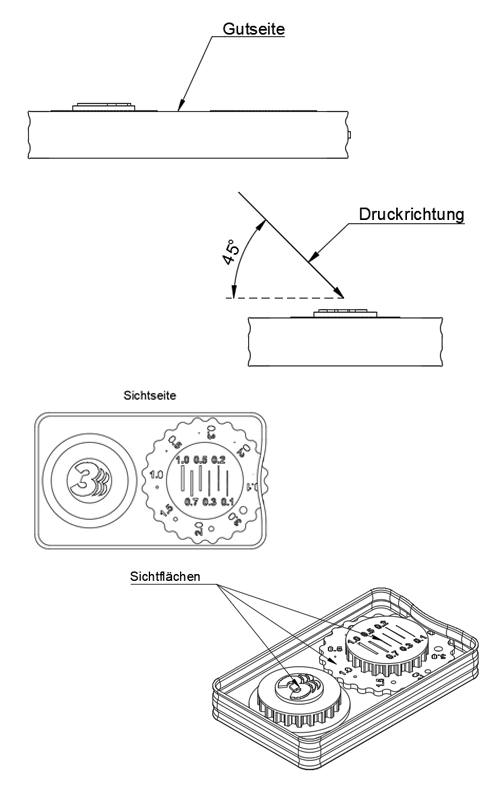

5b) Specifying Component Orientation

You have the option to specify the orientation of the components during the printing process. For this purpose, please upload a technical drawing clearly indicating the desired orientation, for example, by an arrow. This service is offered to you free of charge.

We would like to point out that this option is primarily suitable for experienced users of Multi Jet Fusion technology, as the component orientation has a significant impact on the quality of the finished component.

5c) Quality & Certificates

As a standard, you can commission a initial sample inspection report, a certificate of compliance (inspection certificate 2.2) or an acceptance test certificate (inspection certificate 3.1) through our 3D printing service. For other formats or requirements, please contact our customer service.

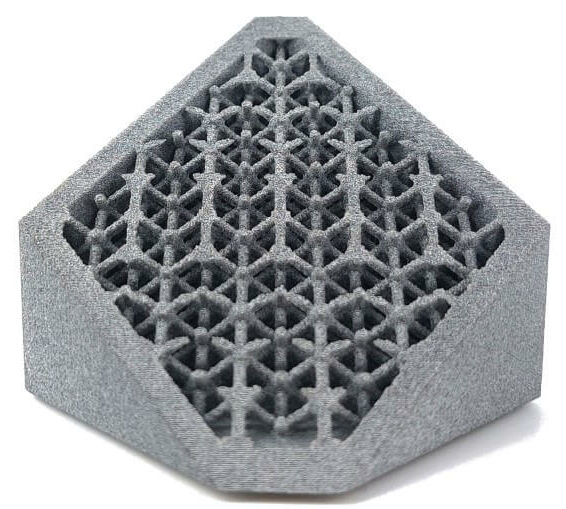

6) Hollowing

When 3D printing solid components with wall thicknesses of approximately 8 mm or more with us, a too high process temperature can occur. This can lead to undesirable effects such as surface damage or increased inaccuracies. Normally, we apply a 3 mm outer skin for such components and fill the body with a lattice network structure. The unsintered powder remains in the part. More information can be found here.