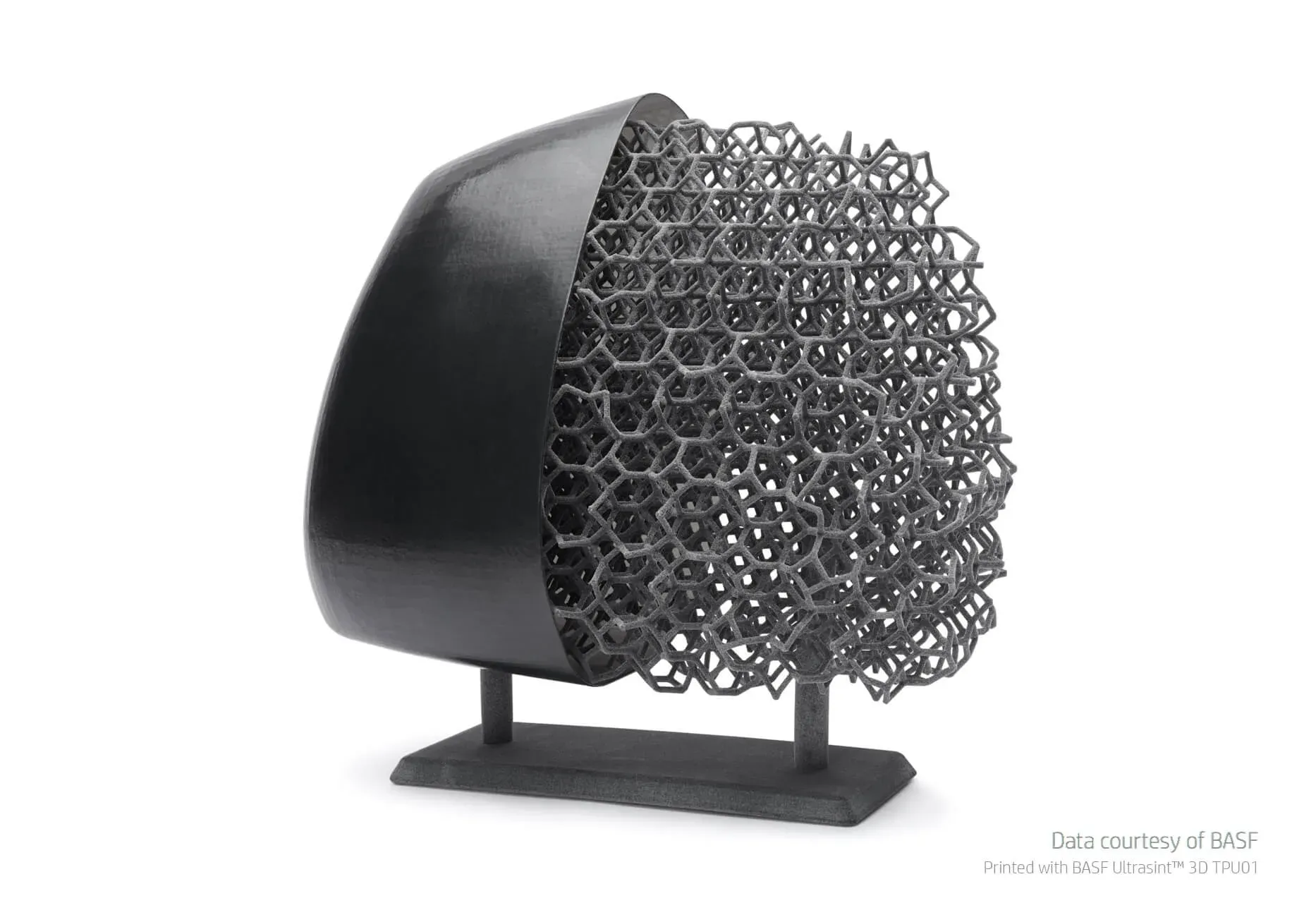

Ultrasint® TPU01 by BASF is a high-quality thermoplastic polyurethane (“TPU”), specifically designed for the Multi Jet Fusion process. This material is characterized by high elasticity and elongation at break, excellent surface quality, high abrasion resistance, and precision in detail. It is perfectly suited for mass production of sports equipment, shoes, automotive interiors, housings or protectors, and industrial tools. Thanks to its powder-based manufacturing and high process stability, it offers limitless design possibilities, enabling the production of even the most complex structures, such as lattice frameworks.

Key Information

Technology

Multi Jet Fusion

Color

Gray

Black

Build Volume

Min. 10 mm

Max. 380 mm

Lead Time

9 working days

Accuracy

Z: ± 1,8 % (min. 1,5 mm)

Properties Manufacturing Tolerance Post-Processing Design Notes Applications Pricing

Material Properties

General Key Figures

- Density: ~ 1.1 g/cm³

- Shore A: 88-90

Tensile Strength, Bending and Impact Properties

| X/Y | Z | |

| Tensile Modulus [MPa]: | 85 | 85 |

| Tensile Strength [MPa]: | 9 | 7 |

| Elongation at Break [%]: | 280 | 150 |

| Flexural Modulus [MPa]: | 75 | 74 |

| Charpy Impact, 23°C [kJ/m²]: | No Break | No Break |

| Charpy Impact, -10°C [kJ/m²]: | 46 | 44 |

Thermal Properties & Flammability

- UL Flammability UL 94: HB

- Vicat Softening Temperature/A (10 N) [°C]: 97 – 98

Electrical Properties

| X/Y | Z | |

| Dielectric Strength [kV/mm]: | 4,38 | 5,81 |

| Volume Resistivity [Ohm-cm]: | 1.45 x 1011 | 6.79 x 1010 |

| Surface Resistivity [Ohm]: | 5.5 x 1011 | Not Tested |

Biocompatibility

- Cytotoxicity – Neutral Red (ISO 10993-5 (2009)): Result – Passed

- In Vivo Sensitization – Local (ISO 10993-10 (2013)): Result – Passed

- In Vitro Skin Irritation (OECD Guideline No. 439): Result – Passed

Surface Properties

Since the raw material is in powder form, the surface produced after 3D printing is slightly rough. The roughness values range from Ra 6 – 12 µm, depending on the geometry and orientation.

Color

In the additive manufacturing process, the white TPU powder is coated with black color. As a result, the interior of the components is completely black, but the surface retains a white component, which contributes to the typical gray production color of Multi Jet Fusion. Due to technical reasons, this coloration is rather inhomogeneous with bright and dark areas.

DOWNLOADS

- Material Datasheet: Extended Material Datasheet TPU – including information about:

- Mechanical Metrics

- Cyclical Mechanical Testing (“ROSS Flex”)

- Chemical Resistance

- UV Stability

- Hydrolysis Resistance

- Air and Liquid Tightness

- Flame and Temperature Resistance

- Air Quality in Vehicle Interiors

- Biocompatibility

- Food Contact

Properties Manufacturing Tolerance Post-Processing Design Notes Applications Pricing

Manufacturing Tolerance

The general tolerance is 1 mm up to 100 mm outside dimension, above 0.9 % in X/Y and 1.5 mm up to 100 mm outside dimension, above 1.8 %. In the case of large-area, flat geometries, warpage may occur in addition. Due to the elastic or flexible material properties, 3D-printed products made of this material are only dimensionally stable to a limited extent and are easily deformable depending on the geometry.

Properties Manufacturing Tolerance Post-Processing Design Notes Applications Pricing

Post-Processing

Painting

Coloring

Coloring in black is possible, but can significantly worsen the dimensional accuracy.

The material tends to swell, which can increase the tolerance by up to 3%. You can find more information under “Accuracy”.

Painting

Wet painting of TPU is possible in principle. However, this should not be used if the component in question is subject to strong dynamic stress, as in such a case the paint could come off at the points of movement.

For more information, please visit Painting.

Minimum Wall Thicknesses

The minimum wall thickness should not be less than 1.2 mm. For longer objects/surfaces or objects subjected to mechanical loads, you should increase the wall thickness.

Cavities

Hollowed objects can be printed, but openings (minimum 10 mm diameter) must be incorporated to allow excess material to be removed. For larger cavities, you should plan for multiple openings. The starting material is compacted during the printing process, making excess material removal challenging.

Clearances

Maintain a minimum clearance of 0.5 mm for grooves or closely spaced walls. Individual objects (“shells”) must be uploaded as separate files unless they are firmly connected.

Resolution

Details as small as approximately 0.5 mm can be represented.

Geared Objects

Interlocking geared objects can be printed. Please observe a minimum distance of 0.5 mm between the objects. Also, ensure that the corresponding areas are accessible for the removal of excess material powder.

Size

The object should not exceed 370 x 274 x 380 mm.

Properties Manufacturing Tolerance Post-processing Design Guidelines Applications Prices

Applications

TPU processed in additive manufacturing (Multi Jet Fusion) is used wherever high loads occur or flexibility is required. The material has been consistently designed for additive serial production and is widely used in industry and medicine.

Shock Absorption/Cushioning

Due to its elasticity, the material can be used for cushioning or shock absorption similar to hard rubber. It is also possible to produce lattice structures for this application. Depending on the wall thickness and geometry of the lattices, different “hardnesses” can be achieved and optimized for the respective application.

Elastic Handles/Grippers

Geometrically complex, workpiece-friendly grippers can be printed for use in robotics or similar applications.

Covers

TPU can be used for housings or protective covers in cases of high impact or dynamic loads.

Orthoses

TPU is ideal for many applications in orthopedics due to its flexibility and durability.

Quote

You can get an instant price quote for your model in our online 3D printing service.

Calculation

The prices are calculated based on machine volume, model surface area, and material usage.

Minimum Order Value

EUR 50,- plus VAT (EUR 59.50 including VAT) / order

Discounts

For higher quantities, reductions of up to approximately 45% compared to the standard price are possible (depending on quantity, component size, and geometry).