This blog article provides a general overview of rapid prototyping. To learn more about our services, please visit the following page: Rapid Prototyping at 3Faktur.

Rapid Prototyping (RP) is currently on everyone’s lips, with many researchers saying that the technology is one of the defining megatrends of the near future. But what does this term actually mean? The term Rapid Prototyping has essentially become an umbrella term for many 3D printing applications. But other manufacturing methods that rely on CNC (Computerized Numerical Control) machines are also part of RP technology. Originally, Rapid Prototyping, as the word suggests, described the rapid production of prototypes and models. Meanwhile, the terms Rapid Tooling (rapid tool production) and Rapid Manufacturing (rapid production of small series and individual pieces) are also included. With the multitude of terms and processes, it’s easy to lose track. In the following article, we will provide you with a brief summary of everything important you should know about Rapid Prototyping technology.

The Term Rapid Prototyping

The term Rapid Prototyping initially described methods for faster production of models, patterns, or simple prototypes using generative manufacturing processes. The starting point is the availability of digital, three-dimensional design data. Important for the implementation of this technology was the development of a data interface that provides an exact description of the object’s geometries and can be used by Rapid Prototyping systems. This was achieved with the development of the STL (STereoLithography) data format.

The STL interface was originally developed for the Stereolithography process and has since proven to be a data standard. Over time, the terms Rapid Tooling and Rapid Manufacturing were also included under Rapid Prototyping. Rapid Tooling is the rapid production of tools and tool inserts, using the same methods as Rapid Prototyping. In contrast to RP and RT, Rapid Manufacturing involves the production of a functional end product. In this case, as with the other two rapid processes, generative manufacturing methods are used. Rapid Manufacturing is particularly interesting for areas where personalized products or components are needed, or where production is customer-oriented and in small quantities.

Manufacturing Processes of Rapid Prototyping

Since Chuck Hull laid the foundation for Rapid Prototyping with the invention of the SLA process in 1984, a multitude of other manufacturing processes have developed. Below is a brief summary of the most widespread processes. If you would like more detailed information, you can find further information on our detailed process pages.

- Multi Jet Fusion: The material powder (mostly PA 12) is fused together. The standard color is gray, and now this process can also print in full color. Suitable for the production of functional prototypes and for serial production.

- 3D Powder Printing: Numerous tenths of a millimeter thick layers of polymer plaster are bonded together in full color. Particularly popular for display/exhibition models due to full color capability.

- Fused Deposition Modeling (FDM): The object is built up from melted plastic droplets by an extruder. Enables rapid, robust plastic models. Leading method for home applications.

- Stereolithography (SLA): A liquid resin is cured using a laser. Enables very accurate and detailed models, also used in the production of personalized products.

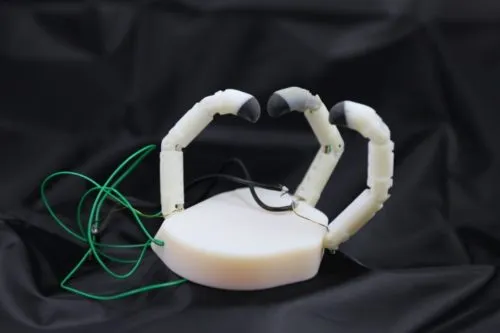

- Polyjet: A print head deposits small drops of a photosensitive polymer onto a work platform, which is immediately cured by a UV laser. The combination of multiple materials is possible during printing, allowing for very realistic prototypes.

- Selective Laser Sintering (SLS)/Selective Laser Melting (SLM): Powdered starting material is melted/sintered into shape using a powerful laser. Both methods are suitable for the production of functional models or small series and allow for the processing of metals.

The following Rapid Prototyping processes are less well-known but still interesting:

- Contour Crafting: Describes the construction of a building using computer-controlled machines. It works similarly to the FDM process, but with concrete and a larger build volume. (More information: Wikipedia)

- Laminated Object Modeling: Individual thin layers of paper are cut into shape and glued together. Similar to the ColorJet process, it can print in color, but results are less uniform compared to LOM. (More information: Wikipedia)

- Electron Beam Melting: Works similar to Selective Laser Melting, but instead of a laser, an electron source melts the metal powder into shape. (More information: Wikipedia)

- Space Puzzle Molding: The aluminum tool (mold) is assembled from many parts instead of (mostly) two parts milled from a block. (More information: Wikipedia)

- Laser Engineered Net Shaping: also known as “Laser Powder Forming,” is a process where metal powder is deposited through a nozzle and immediately melted into place by high-energy lasers at predetermined locations. Scientists working for NASA have even 3D printed lunar regolith using this method. (More information: Wikipedia)

Image: Washington State University

Advantages of Rapid Prototyping

The major advantage of Rapid Prototyping processes is that you can reach a model, prototype, or tool much faster. The manufacturing time varies depending on the chosen manufacturing process and also depends on the size and complexity of the object, as well as the quality and printability of the existing 3D model. In most cases, the object can be produced in no more than a few days. This high speed of production enables models/prototypes to be used much more frequently. RP objects are excellent for demonstration or functional models and help to significantly increase the motivation of all involved. Furthermore, errors in design or conception are better and faster recognized with a real model. The earlier design errors are detected, the more cost-effective and less time-consuming they can be corrected.

In addition to speed, Rapid Prototyping technologies also bring another advantage. Due to the generative construction of objects, a large part of the waste that would occur with other processes such as milling, turning, or grinding is eliminated. This is not only to be considered for cost reasons but also conserves resources. In processes using a powder bed, the unused material can usually be reused for further prints. For SLA, FDM, and Polyjet processes, support material is necessary for some shapes, which needs to be removed after printing. However, with clever modeling, this can be minimized.

Rapid Prototyping reaches its cost-related limits when you plan to start normal (above small series) or large-scale production. However, for small quantities up to a few thousand pieces, RP processes offer not only a speed advantage but also a cost advantage over traditional manufacturing methods. Especially if you offer personalized/individual products to your customers or want to create three-dimensional objects yourself, Rapid Prototyping processes unfold their potential.

Another trend associated with the establishment of Rapid Prototyping is a beginning re-regionalization. The continuously falling acquisition costs for Rapid Prototyping systems make it increasingly possible for more companies to buy their own system and independently produce their models, prototypes, or end products. Private users can use this technology to produce spare parts or gadgets themselves and become independent of other manufacturers or suppliers. Anyone can now become a “manufacturer,” all you need is a 3D printer and a printable digital 3D model.

About 3Faktur: 3Faktur is a specialist in 3D printing, Rapid Prototyping, and Rapid Manufacturing. We work with the Multi Jet Fusion process from HP and offer different materials for prototype construction and series production. If you have any questions about your project, feel free to contact us.