Services Benefits Automation Manufacturing Technology Materials Surface Processing & Finishing Quality

3Faktur is an industrial 3D printing service provider. On behalf of our more than 2.500 customers from the mechanical engineering, medical technology, automotive, high-tech, orthopaedics and many other industries, we manufacture plastic components as series parts (“additive manufacturing“) or one-offs (“rapid prototyping“) using 3D printing.

More than 150.000 additive series components leave our factory every year. We attach great importance to the direct control of our production processes in order to optimally coordinate all workflows: from production-oriented design for additive manufacturing to optimally coordinated 3D printers and an integrated and largely automated process chain consisting of post-processing and quality assurance.

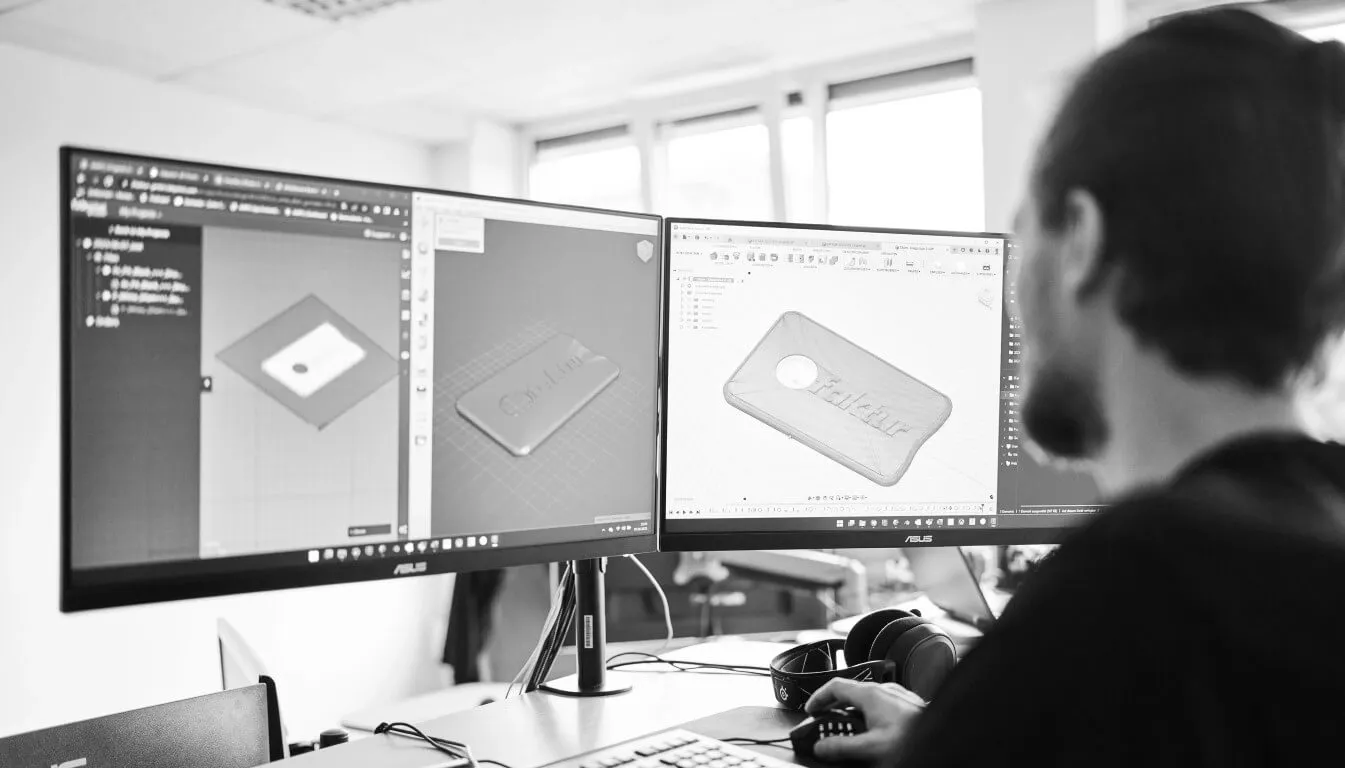

Design & Engineering

We support you in optimizing the design of your components for 3D printing.

Design Optimization

Additive Manufacturing

We manufacture your components using 3D printing on-demand in the materials polyamide 12, polyamide 12 W, polyamide 11 and TPU.

Material Overview

Finishing

For the finishing touches to your components, we offer numerous surface finishing options, such as chemical smoothing or DeepDye coloring.

Surface FinishingServices Benefits Automation Manufacturing Technology Materials Surface Processing & Finishing Quality

Your Benefits with 3Faktur

Controlled Quality

All process steps are standardized, documented and strictly controlled. Continuously tested material quality, perfectly maintained and specialized plant technology, a controlled production environment and extensive final inspections – at 3Faktur, we leave nothing to chance and focus on replicable high quality.

Maximum Reliability

3D printing makes it possible to provide your parts and components exactly when you need them – ‘just in time’. In order to meet your requirements in every respect, we attach great importance to what is most important to you: a delivery that not only impresses with its punctuality, but also with consistently high and consistent quality standards.

Customer-Oriented Service

Support when necessary – efficiency when possible. We are there for you when you need us, whether for questions or in the design phase for your projects. Once everything has been clarified, the focus is on efficiency: fast order processing and intuitive tools, such as our online portal for automated price calculations and orders, simplify your work. We make it easy for you, without time-consuming complexity.

Services Benefits Automation Manufacturing Technology Materials Surface Processing & Finishing Quality

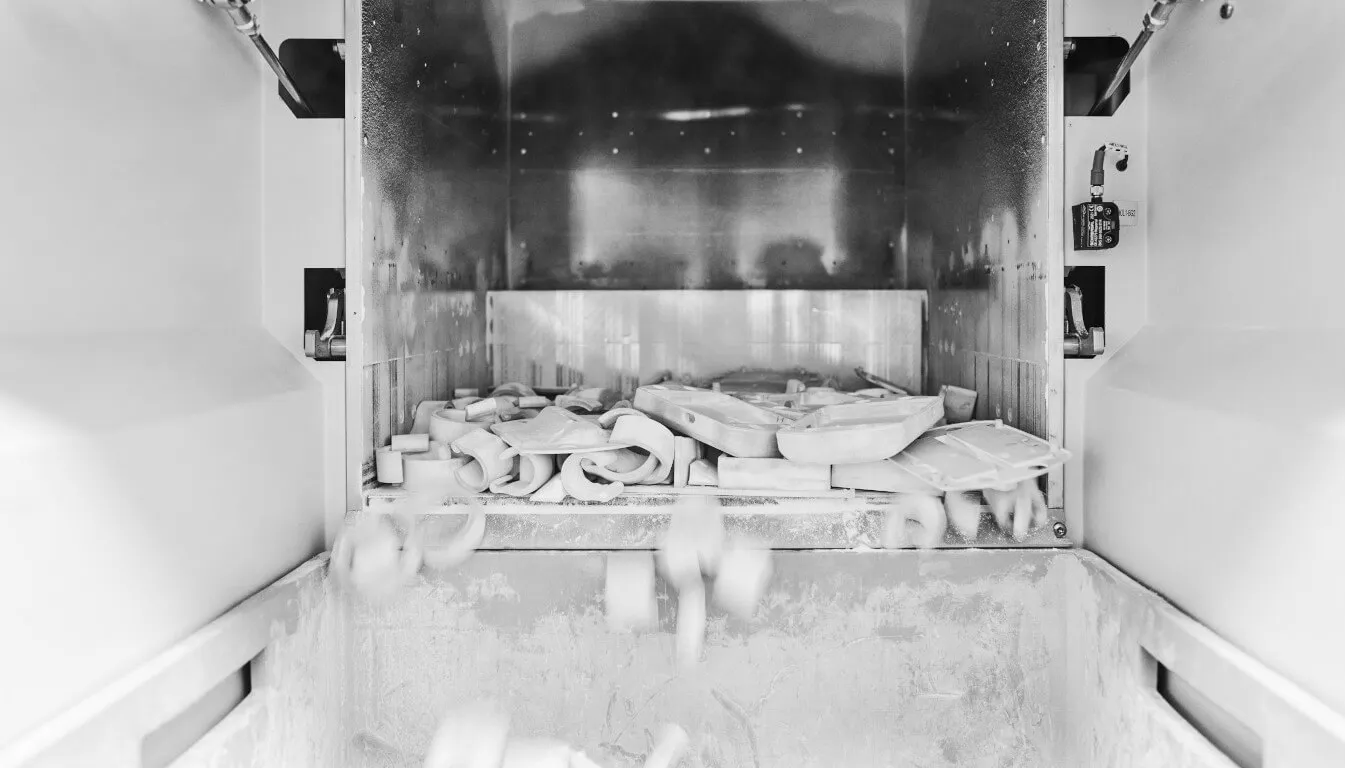

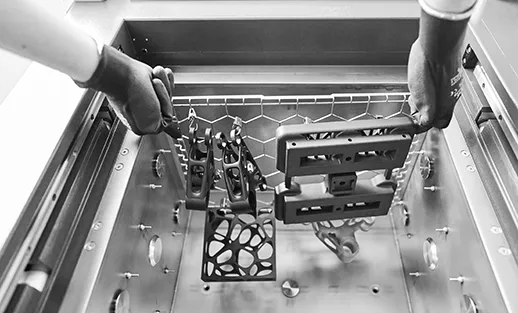

State of the Art Digital Manufacturing

At 3Faktur, additive manufacturing is consistently designed for series production and industrial requirements. High technology is used for this, e.g. with automated component depowdering, AI-based component recognition & sorting, automated packaging and state-of-the-art, automated quality controls. This makes us a pioneer in the digital production of plastic components. For the customers of our 3D printing service, this means the highest possible quality standards, maximum repeatability and competitive prices thanks to optimum efficiency.

Services Benefits Automation Manufacturing Technology Materials Surface Processing & Finishing Quality

Manufacturing Technology

Multi Jet Fusion is a powder-based, additive manufacturing technology. The process was specifically developed for industrial use and therefore differs significantly from more prototype-oriented 3D printing methods.

3Faktur was one of the first users of Multi Jet Fusion and is now one of the top 5 3D printing services using this technology in Europe. This specialization enables us to achieve a highly optimized production environment with quality-oriented processes, an extensive process chain and an industry-leading level of automation.

Services Benefits Automation Manufacturing Technology Materials Surface Processing & Finishing Quality

MATERIALS: INDUSTRIAL THERMOPLASTICS FOR THE HIGHEST DEMANDS

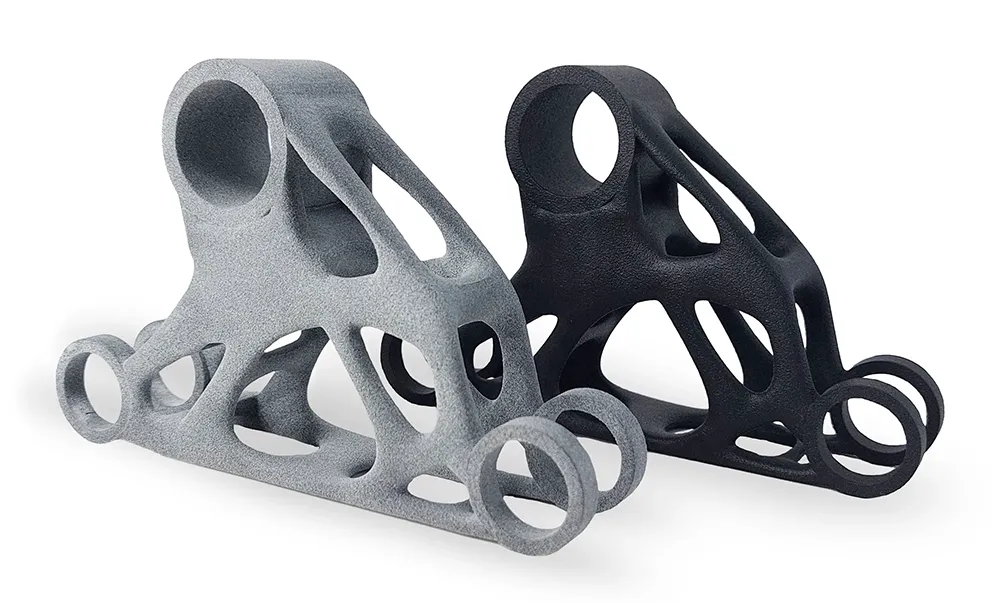

PA 12

Polyamide 12 (PA 12) is the versatile technical plastic known for its robustness, chemical resistance, and durability. Its impressive mechanical and thermal strength makes it suitable for a wide range of applications.

PA 12 W (White)

PA 12 W, the first white material for Multi Jet Fusion, is as resilient and durable as gray PA 12 and can be colored as desired. It maintains color stability and mechanical properties even when exposed to UV radiation.

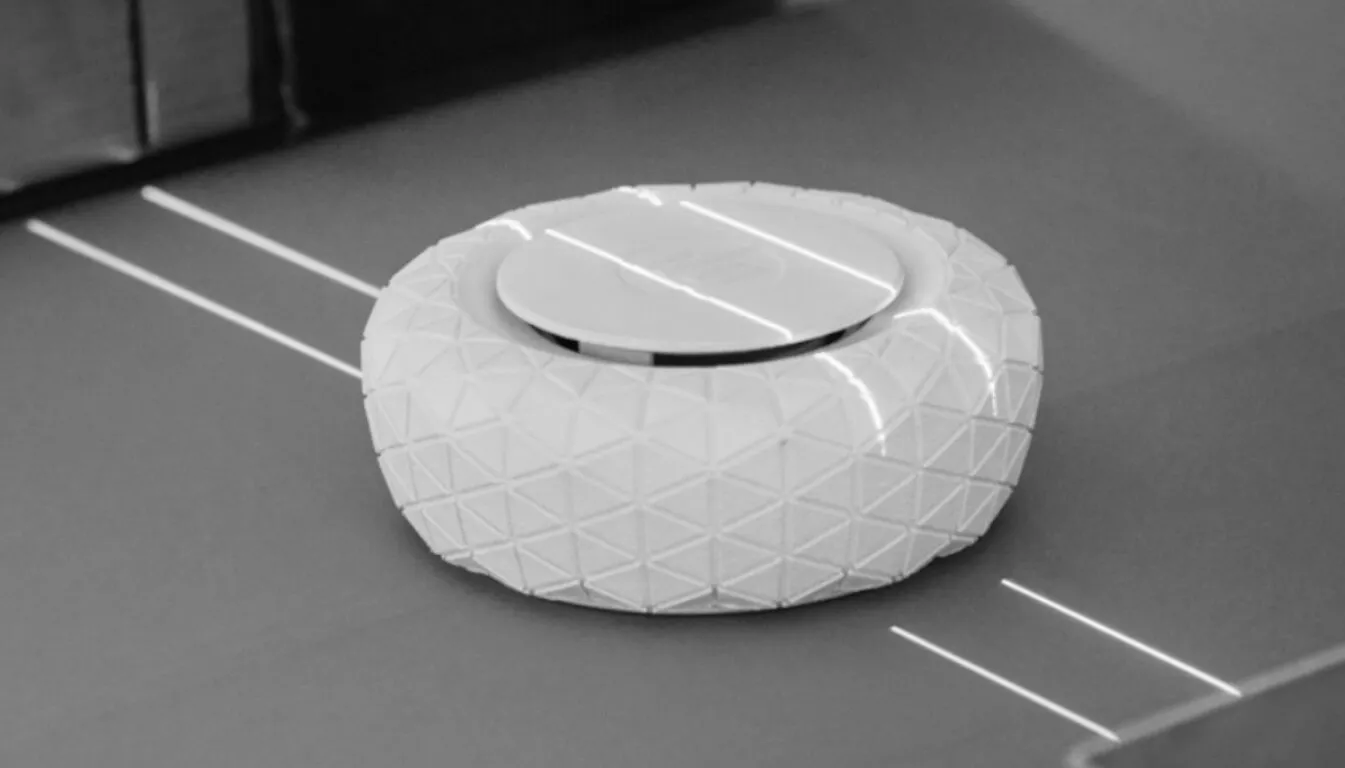

TPU

BASF Ultrasint TPU is an elastic plastic with a Shore hardness of 88 – 90A. The material is used for dampening, grips, seals, orthoses, grippers, or heavily stressed housings and covers.

PA 11

PA 11, sourced from renewable resources, surpasses PA 12 in flexibility and impact resistance. The material’s toughness makes it ideal for film hinges, snap fasteners, and robust orthoses.

Services Benefits Automation Manufacturing Technology Materials Surface Processing & Finishing Quality

Surface Processing & Finishing

Dyeing

Coloring grey base material (PA 12, PA 11, TPU) into black or white base material (PA 12 W) into bright colors.

Shot Peening

Surface treatment resulting in densification, increased scratch resistance and improvement of haptics as well as aesthetics.

Vapor Smoothing

Surface treatment (chemical smoothing) with the help of a solvent. The result is a smooth and almost non-porous surface, which is gas- and waterproof.

Services Benefits Automation Manufacturing Technology Materials Surface Processing & Finishing Quality

QUALITY MANAGEMENT AT 3FAKTUR

As a certified industrial AM production facility according to ISO/ASTM 52920, 3Faktur offers you the highest standard of industrial additive manufacturing. Our quality management is certified according to ISO 9001:2015.

High Degree of Specialization

We focus on one 3D printing technology as the basis for highly qualified additive manufacturing of industrial plastic components. This is based on our highly optimized in-house process chain, including post-processing options such as shot peening and vapor smoothing.

High Degree of Automation

We rely on automation of our production processes to increase replicability and keep delivery times short and prices low for you. The same applies to our fully digitized, documented, and certified business processes.

Good News!

3D printing is one of the most exciting technologies of our time. Stay up to date on the latest developments and benefit from current offers from 3Faktur.

Sign up for our newsletter!