- Technology: Plastic powder is wetted with a heat-conductive liquid and melted using infrared light. More…

- Typical quantities: 1 – 5.000 pieces

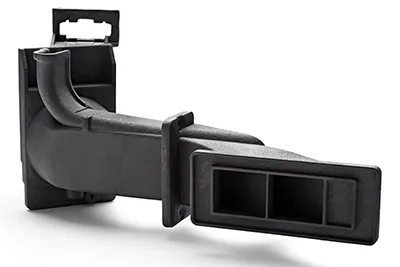

- Applications: Functional plastic parts as a series or individual production

- Build volume:

- 370 x 274 x 380 mm

Visit our Multi Jet Fusion page to learn more about the process.

Multi Jet Fusion PA 12 (Polyamide 12) PA 12 W (Polyamide 12 white) BASF Ultrasint TPU01 PA 11 (Polyamide 11)

PA 12 (Polyamide 12)

Material properties

Strong, mechanically durable, long-lasting, suitable for demanding applications

Color

Gray or black

Typical applications

Housings, mechanical and structural components, components for handling gases and liquids, decorative elements, fixtures

For further information, visit our PA 12 page.

Multi Jet Fusion PA 12 (Polyamide 12) PA 12 W (Polyamide 12 white) BASF Ultrasint TPU01 PA 11 (Polyamide 11)

PA 12 W (Polyamide 12 white)

Material properties

The material properties are comparable to PA 12, with the main difference being the color.

Color

White and 17 bright colors, e.g. various shades of green, blue and red as well as orange, yellow, grey and others.

Typical applications

Housings, decorative elements, and other functional visible components

Visit our PA 12 W page for more information.

Multi Jet Fusion PA 12 (Polyamide 12) PA 12 W (Polyamide 12 white) BASF Ultrasint TPU01 PA 11 (Polyamide 11)

TPU (BASF Ultrasint TPU01)

Material properties

High elasticity (Shore A 88 – 90), and elongation at break, similar to hard rubber.

Color

Gray or black

Typical applications

Protective enclosures, cushioning elements (mesh structures), devices for sensitive surfaces & high temperatures, orthotics.

For more information, visit our TPU page.

Multi Jet Fusion PA 12 (Polyamide 12) PA 12 W (Polyamide 12 white) BASF Ultrasint TPU01 PA 11 (Polyamide 11)

PA 11 (Polyamide 11)

Data courtesy of HP

Material Properties

Flexible material with high breaking elongation and toughness.

Color

Gray or black

Typical Applications

Components with flexible elements such as film hinges, snap connections and orthoses.

Visit our PA 11 page for more information.