PA 12 W is a polyamide 12 and differs from our standard PA 12 (HP High Reusability PA 12) mainly in color. PA 12 W is white and can be dyed as desired. The material is processed using the Multi Jet Fusion 3D printing process. It is a rigid, high-quality, and versatile plastic designed for additive serial production.

Quick Information

Technology

Multi Jet Fusion

Color

White, Colored

Build Volume

min. 10 mm

max. 380 mm

Production Time

Standard:

7 working days

Accuracy

± 0.3 %

(min. ± 0.3 mm)

Properties Manufacturing Tolerance Post-Processing Design Guidelines Applications Prices

Material Properties

Mechanical Properties

- Tensile Strength: ~ 48 ± 5 MPa

- Elongation at Break: 13 ± 6 %

- E-Modulus: 1,500 ± 200 MPa

- Density: ~0.9 – 1.0 g /cm³ (geometry-dependent)

Polyamide 12 is a solid, highly resilient, and durable plastic. The material properties are largely isotropic (similar mechanical characteristics in all orientations).

Thermal Resistance

- Heat Deflection Temperature (HDT) at 0.45 MPa: 175 °C

- Heat Deflection Temperature (HDT) at 1.82 MPa: 95 °C

For continuous loads, 95 °C should not be exceeded. For short-term loads, up to a maximum of 120 °C is possible depending on the geometry. Especially with thin wall thicknesses (< 2 mm) and/or simultaneous mechanical or dynamic stress, the load-bearing capacity is reduced.

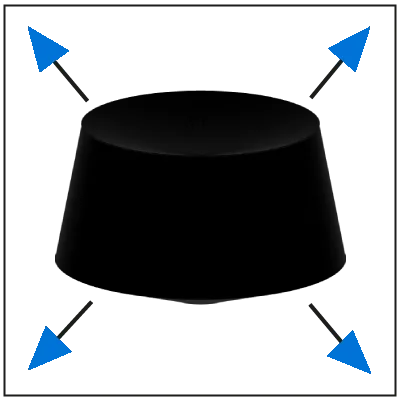

Surface Properties

- Roughness Ra Bottom: 5 ± 2 µm

- Roughness Ra Top: 10 ± 2 µm

- Roughness Ra Slope (45°): 8 ± 2 µm

The raw material used in Multi Jet Fusion is in powder form. This results in a slightly rough surface, similar to fine sandpaper. The typical 3D printing layer lines (print lines) are visible with shallow angles (up to about 15°) and are relatively fine due to the layer thickness of only 80 µm.

Colors

Off-white, slightly bluish color cast. The color is stable even under UV exposure and does not yellow (Delta E deviation below 2.5 / 1,000 hrs).

DOWNLOADS

Material Datasheet: PA 12 W Material Datasheet

Properties Manufacturing Tolerance Post-Processing Design Guidelines Applications Prices

Manufacturing Tolerance

The general tolerance is 0.3 mm up to an outer dimension of 100 mm, and 0.3 % above this. In the case of large, flat geometries, distortion may also occur.

Properties Manufacturing Tolerance Post-Processing Design Guidelines Applications Prices

Post-Processing

PA 12 W can be dyed. The Deep Dye Coloring process developed by Dyemansion is used for this purpose. The coloring is UV stable.

- Delivery time: + 5 working days

- Price: Depends on quantity and size. Minimum order value of EUR 150 per color.

For more information, please refer to Dyeing.

Vapor Smoothing (Chemical Smoothing)

Chemical surface treatment that produces a non-porous surface with reduced roughness. Major applications are liquid or gas carrying components, components where easy cleaning is required (medical, clean room) or as a basis for subsequent coating processes (reduction ‘outgassing’, reduction porosity, smoothing). More Information

Notes on ordering

Delivery time: + 5 working days Price: depending on number of pieces and size, typical unit costs of approx. EUR 7 – EUR 10; plus VAT.

Properties Manufacturing Tolerance Post-Processing Design Guidelines Applications Prices

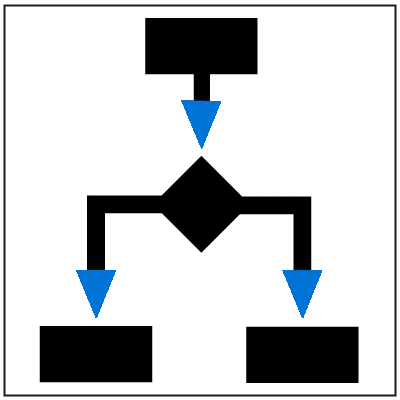

Design Guidelines

Minimum Wall Thickness

The minimum wall thickness should not be less than 1 mm. For longer objects/surfaces or objects exposed to mechanical stresses, it is advisable to increase the wall thickness.

Cavities

Hollowed objects can be printed, but openings (minimum 10 mm in diameter) need to be incorporated to allow the removal of excess material. For larger cavities, it is recommended to include multiple openings. The initial material is compressed during the printing process, making it challenging to remove excess material.

Distances

Maintain a minimum distance of 0.5 mm for grooves or closely spaced walls. Individual objects (“shells”) must be uploaded as separate files unless they are firmly connected.

Resolution

Details as small as approximately 0.5 mm can be represented.

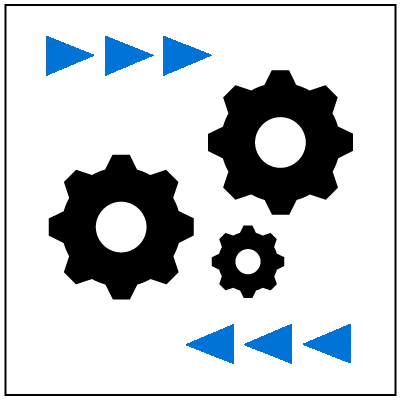

Geared Objects

Interlocking geared objects can be printed. Please ensure a minimum distance of 0.5 mm between the objects. Also, make sure that the corresponding areas are accessible for the removal of excess material powder.

Size

The object should not exceed 370 x 274 x 380 mm in size.

Properties Manufacturing Tolerance Post-processing Design Guidelines Applications Prices

Applications

The material PA 12 W can be used for both rapid prototyping and additive series production. The material differs from our standard PA 12 in color, but the mechanical properties are comparable. PA 12 W is white and can be colored in numerous colors.

Therefore, PA 12 W is particularly suitable for white and colored components in the visible area. The applications include, for example:

Housings

Due to its high mechanical strength and the possibility of coloring the durable and robust material, it is ideal for applications in housings and panels.

Orthoses

Depending on the required properties, Polyamide 12 is used in addition to TPU. PA 12 W enables the production of colored orthoses.

Consumer Products

In consumer products, colors often play a greater role than in industrial components. PA 12 W offers versatile possibilities for the production of white and colored products and product components.

Quote

You can get an instant price quote for your model in our online 3D printing service.

Calculation

Prices are calculated based on machine volume, model surface area, and material usage, among other factors.

Minimum Order Value

EUR 50,- excl. VAT (EUR 59.50 incl. VAT) / order

Discounts

For larger quantities, significant reductions compared to the standard price are possible, depending on the quantity, component size, and geometry.