With PA 12 | Smooth (HP HR PA 12 S, enabled by Arkema), we manufacture your components directly with an exceptionally smooth and homogeneous surface. The particularly fine and uniform powder grain of the raw material minimizes roughness, so in many cases, even for visible parts, no additional post-processing is required.

For you, this means: aesthetically high-quality results and reduced costs. Ideal for all applications where first-class surface quality and efficiency are required.

Quick Facts

Technology

Multi Jet Fusion

Colors

gray

black (dyed)

Build Volume

min. 10 mm

max. 380 mm

Production Time

3 business days (Priority)

6 business days (Standard)

12 business days (Flex)

Accuracy

± 0.3 %

(min. ± 0.3 mm)

Material Properties of PA 12 | Smooth

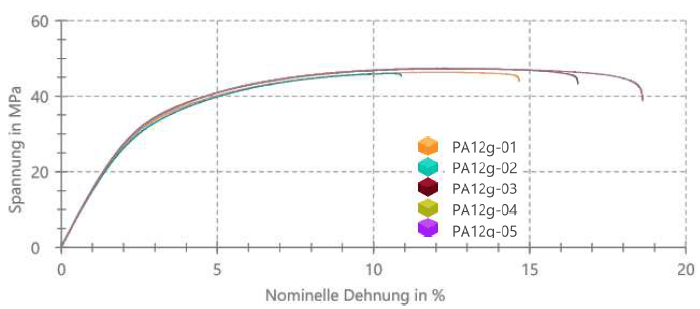

Mechanical Properties

HP 3D HR PA 12 S offers solid mechanical strength, which is, however, slightly lower compared to PA 12 | Classic – especially in the Z-axis. This difference becomes particularly noticeable with very thin wall thicknesses (< 1 mm); therefore, we recommend a minimum wall thickness of 1 mm instead of 0.7 mm in these cases.

A significant advantage: the exceptional UV stability. After just a few hours of direct sunlight, PA 12 | Smooth increases its mechanical strength and permanently surpasses PA 12 | Classic under UV exposure. This makes the material particularly suitable for outdoor parts or applications with high UV exposure.

- Tensile strength: ~ 45 MPa

- Elongation at break: 12 % (XY) or 6 % (Z)

- Young’s modulus: ~ 1,700 MPa

- Density: ~0.98 g /cm³ (geometry-dependent)

Thermal Properties

For continuous use, 95 °C should not be exceeded. For short-term exposure, up to 120 °C is possible depending on geometry. In particular, with thin wall thicknesses (< 2 mm) and/or simultaneous mechanical stress, load capacity is reduced.

Surface Properties

The raw material polyamide 12, processed using Multi Jet Fusion, is in powder form. This results in a slightly rough surface, similar to fine sandpaper. Since the grain size of PA 12 | Smooth is finer and more uniform, its roughness is the lowest of our polyamide 12 variants.

The typical stair-step effects of 3D printing (printing lines) are visible at shallow angles (up to approx. 15°) and are relatively fine, as the layer thickness is only 80 µm.

- Roughness Ra bottom side: 3 ± 2 µm

- Roughness Ra top side: 5 ± 2 µm

- Roughness Ra slope (45°): 4 ± 2 µm

Color

In the 3D printing process (more details on Multi Jet Fusion), the white PA 12 powder is given a black color. The parts are therefore completely black on the inside. On the surface, a white portion remains, consisting partly of sintered white powder grains. This results in the typical gray production color. Due to technical reasons, this is rather inhomogeneous with light and dark areas.

Optionally, a black dyeing process is possible, in which the remaining white portion is pigmented. The result is homogeneous, completely black parts (i.e., also on the inside).

Downloads

- Material data sheet: Material Data Sheet PA 12 | Smooth (HP 3D HR PA 12 S, enabled by Arkema)

Manufacturing Tolerance

The general tolerance for Polyamide 12 | Smooth is ± 0.3 mm up to 100 mm outer dimension, above that ±0.3 %. For large, flat geometries, warping may also occur.

Post-Processing of PA 12 | Smooth

Black Dyeing & Shot Peening

Recommended for visible parts: Dyeing followed by surface compaction for an optically and haptically high-quality surface

Ordering Information

- Delivery time: + 1 business day

- Price: depending on quantity and size, typical unit costs of approx. EUR 1 – EUR 10 excl. VAT

- Maximum size: 350 x 250 x 150 mm

More information can be found on our Dyeing page. Colored finishes are possible with PA 12 | White.

Vapor Smoothing (Chemical Smoothing)

Chemical surface treatment, creating a pore-free surface with reduced roughness. Main applications include fluid- or gas-carrying components, parts requiring easy cleaning (medical, cleanroom), or as a basis for subsequent coating processes (reducing “outgassing”, reducing porosity, smoothing).

Ordering Information

- Delivery time: + 3 business days

- Price: depending on quantity and size, typical unit costs of approx. EUR 5 – EUR 10 excl. VAT

Further information can be found under Chemical Smoothing.

Coating (Wet Painting)

In wet painting, a paint specifically formulated for polyamide 12 is applied.

Ordering Information

- Lead time: + approx. 2 weeks

- Price: strongly dependent on size and quantity. Note: the minimum order value for processing is EUR 100 excl. VAT.

Learn more on our Coating page.

Design Guidelines

Here is a brief overview of the most important rules for designing your additively manufactured parts. You can find more detailed information and tutorials on design for 3D printing.

Minimum wall thickness

The minimum wall thickness is 1 mm. For longer objects/surfaces or parts subject to mechanical loads, you should increase the wall thickness accordingly.

Hollow spaces

Hollowed objects can be printed, but openings (min. 10 mm diameter) must be added so that excess material can be removed. For larger cavities, you should plan several openings. The raw material becomes compacted during the printing process; therefore, excess material is very difficult to remove.

Clearances

Maintain a clearance of at least 0.5 mm for grooves or closely spaced walls.

Individual objects (“shells”) must always be uploaded as separate files unless they are permanently connected to each other.

Resolution

Details down to around 0.5 mm can be reproduced.

Interlocking objects

Interlocking objects can be printed. Please observe a minimum clearance between parts of 0.5 mm. Also ensure that the relevant areas are accessible so that excess powder material can be removed.

Size

The object should not exceed 370 x 274 x 380 mm.

Prices

Quote

You can get an instant quote for your model in our online 3D printing service.

Calculation

Prices depend, among other factors, on machine volume, model surface area, and material usage.

Express surcharge approx. 25 %

Minimum order value

EUR 50 excl. VAT (EUR 59.50 incl. VAT) per order

Discounts

For higher quantities, a significant reduction compared to the standard price is possible, depending on quantity, part size, and geometry.