Multi Jet Fusion (MJF)

The Multi Jet Fusion (MJF) process is a powder-based 3D printing method for the efficient production of demanding, industrial plastic parts. Unlike conventional prototyping technologies, MJF is not only suitable for prototype production but also for the production of small to medium series of industrial parts.

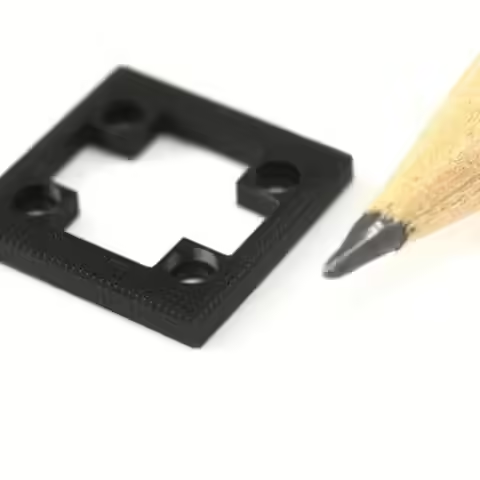

Precision Micro 3D Printing

Precision Micro 3D Printing, technically known as Precision Micro Stereolithography (PµSL), from Boston Micro Fabrication (BMF), is a process for producing high-precision, miniaturized parts. It is used in microfluidics, electronic components, and the manufacturing of precision parts.

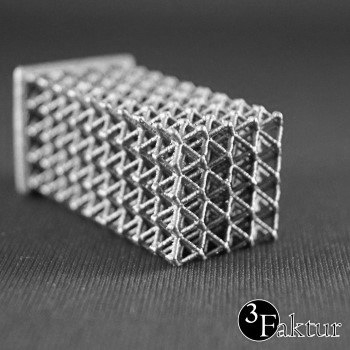

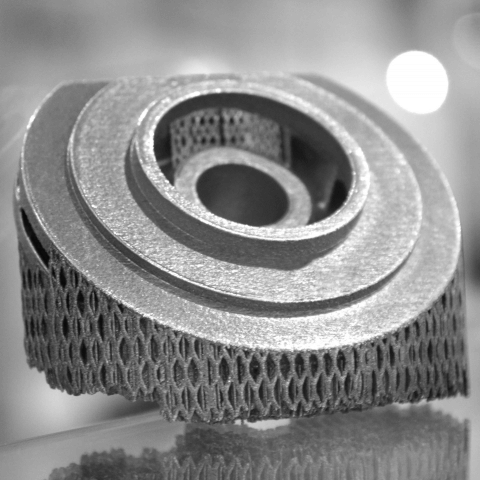

Metal 3D Printing

Metal laser melting (also known as Selective Laser Melting, SLM) is an additive manufacturing process for producing complex, high-strength metal parts. By layer-by-layer melting of metal powder using a laser, precise and durable components for various industrial applications can be produced.