Additive Manufacturing

3Faktur is a leading 3D printing service provider specializing in the additive serial production of industrial plastic components. Week after week, we manufacture thousands of parts for over 2,000 customers from various industries such as mechanical engineering, high-tech, medical technology, automotive industry, electronics, and more.

Industrial 3D printing allows for the flexible production of series components, enabling customers to order flexible quantities and make design modifications as needed. In terms of requirements, such as meeting technical specifications and delivery reliability, additive serial production does not differ from conventional processes. However, the flexible production requires special attention to reproducibility.

3Faktur has focused precisely on that and offers an optimized, documented, and certified process chain specifically designed for serial production. As a result, the company positions itself as one of the leading providers of additive serial production of plastic components in Europe. For our customers, this means reliable quality, reproducibility, and dependable, short delivery times at highly competitive prices.

For information on the quotation and ordering process, click here.

Our Portfolio of Additive Manufacturing Services

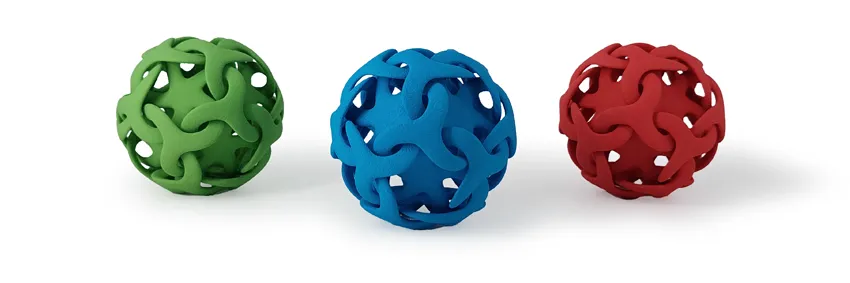

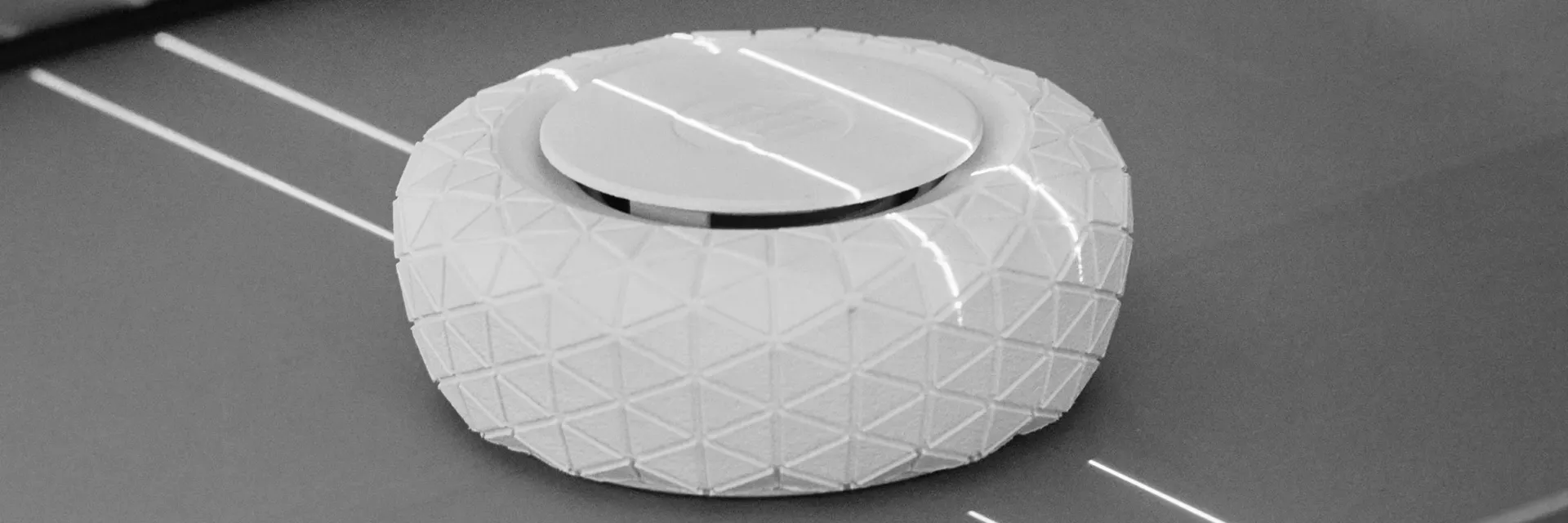

Specializing in an industrial 3D printing process, the Multi Jet Fusion process, allows us to ensure consistently high product quality and process stability. The use of different materials and finishing options creates a portfolio that covers many industrial use cases. Moving variability to the end of the process chain keeps processes simple and therefore stable. The goal is to exceed your requirements and to do so replicably, error-free and at fair prices.

Portfolio Overview

Quality

First Article Inspection Report (FAIR)

Certificate of Compliance (Test Certificate 2.2) & Acceptance Test Certificate (Inspection Certificate 3.1)

Certified QMS and Certified Industrial Additive Manufacturing Facility

Additive Manufacturing Portfolio Process Chain Reproducibility Process Tracking Quality Control

State of the Art Digital Manufacturing

At 3Faktur, we don’t just consider 3D printing in isolation, but take a holistic perspective on digital production. This includes the upstream and downstream process chains. To ensure the highest quality and efficiency, all elements must seamlessly interact. To optimize 3D printing, we have compiled some recommendations under “Design Guidelines for Additive Manufacturing” to help you optimize your design.

The particular challenge in additive manufacturing lies in the so-called “High Mix / Low Volume” situation. This often involves frequent orders but in small quantities. Therefore, we produce a relatively small quantity (“Low Volume”) of geometrically diverse parts (“High Mix”) every day. To comprehensively meet the specifications in all cases, innovative processes and solutions are required.

High Tech for Improved Reproducibility

To ensure this, we consistently rely on digitization and automation. For example, in preprocessing, such as component inspection and print preparation, we use artificial intelligence developed by us. It checks, for example, whether the component has already been successfully produced in the same or a previous version and determines the production parameters accordingly to ensure the best possible reproducibility.

Automation solutions are also used in various other process steps. For example, the unpacking and depowdering of the produced parts are largely automated. This ensures consistent and reproducible surface quality, even for subsequent processes such as dyeing by immersion.

Comprehensive Process Tracking for Transparency and Quality Assurance

To ensure the highest level of transparency and quality assurance, we track and document all relevant process steps in real-time. This includes the tracking of the 3D printing process itself. We monitor and record critical parameters such as temperature, pressure, and build time to identify any deviations or anomalies that may affect the quality of the printed parts.

Furthermore, we track the entire post-processing chain, from unpacking and depowdering to any subsequent surface treatments or inspections. This comprehensive process tracking allows us to quickly identify and resolve any issues that may arise, ensuring consistent quality throughout the production process.

State-of-the-Art Measurement Technology for Consistent Product Quality

At 3Faktur, we have introduced state-of-the-art measurement technologies to ensure consistent product quality throughout the production process. This includes real-time monitoring and inspection of the 3D printing process itself.

We use advanced technologies such as vision systems and process monitoring sensors to detect and resolve any issues that may arise during the printing process. These systems can detect anomalies, such as problems with layer adhesion or dimensional inaccuracies, and initiate immediate corrective action.

By implementing these advanced measurement technologies, we can detect and resolve potential quality issues at an early stage, ensuring that the printed end products meet the highest quality and reliability standards.