Creating 3D Models for 3D Printing:

Unfortunately, not all 3D models are suitable for 3D printing. While visually impressive 3D models may suffice for virtual applications, certain criteria must be met for 3D printing. This includes defining the shape and, in the case of color 3D printing, the color. However, there are other critical criteria as well. For example, it is important for 3D printing that the orientation of the surfaces (‘normals’) is clearly defined. We have compiled the most important design criteria for you:

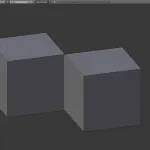

1. Edge Connectivity

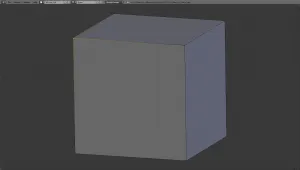

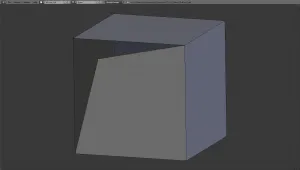

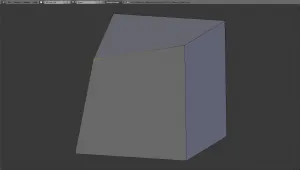

Two adjacent surfaces do not necessarily form a connected mesh. When creating your 3D models, ensure that edges are fully connected, so they form a ‘shared’ mesh instead of two separate ones. You can visualize this by moving a corner – if it’s a closed edge, both surfaces move; if it’s unconnected edges, only one surface moves (see figures).

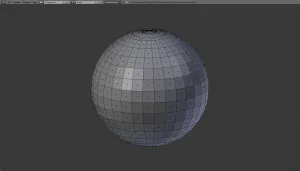

2. Closed Volume – ‘Watertight’

Only volumes can be 3D printed, not individual surfaces (i.e., there must be a certain wall thickness). In your 3D model, extrude surfaces or combine multiple surfaces to create a volume. This volume must be fully closed, meaning there must be no holes (missing polygons) present. The latter can sometimes happen ‘accidentally’ during certain operations, such as boolean operations.

Surface orientation is also important; if a single surface in the mesh has an incorrect orientation (‘normal’), it will have the same effect as a hole.

In most 3D programs, the inner and outer sides are differentiated by color; for example, in Blender, the outside is gray and the inside is dark blue. In Blender, you can use the ‘Solid Check’ tool in the 3D Print Toolbox to check if your model is watertight.

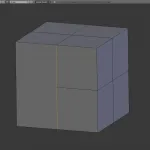

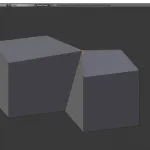

3. Avoid Manifold Issues

Each edge can only connect two surfaces. Imagine you have two equal-sized cubes and move them so that they are edge-to-edge. If the edges are separated, they form two separate volumes. However, if they share the same edge, that edge would connect four surfaces. Such a construct would not be suitable for printing and must be avoided.

4. Excess Volumes

Operations like scaling the 3D model or using 3D scanning technology can sometimes lead to the formation of unnecessary volumes (called second-order shells). These are sometimes ‘useless’ structures that often exist freely in space and cause no obvious harm. However, such structures can jeopardize the 3D printing process. For example, if an additional structure forms inside a cavity, it can close escape holes from which material should be recovered, leading to a significant increase in costs. Additionally, excessive structures can merge with other models or structures during printing, rendering the model unusable. Best practice is to remove all excess structures from the model before printing.

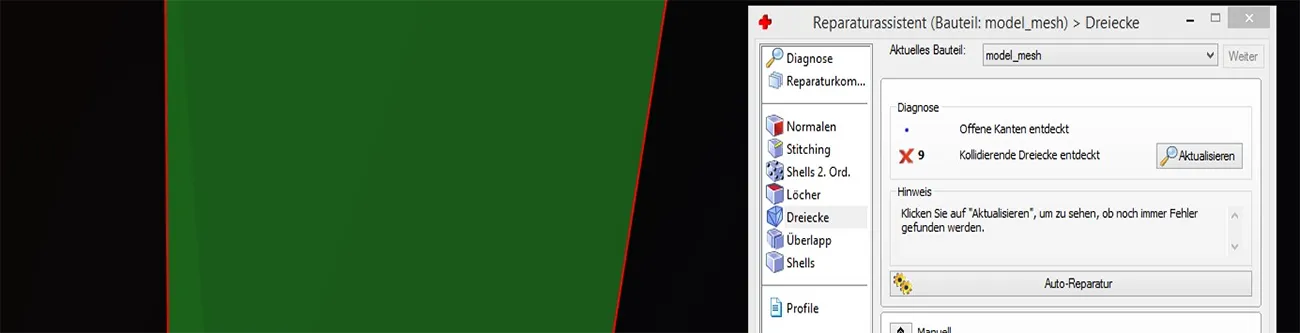

5. Colliding Triangles

When triangles intersect, this can cause problems in some printing processes. While this usually doesn’t cause issues in powder printing processes, it can lead to complications in FDM printing. It’s optimal to completely avoid polygon collisions during 3D design. Unfortunately, collisions frequently occur in some 3D scanning methods and may need to be manually corrected if in doubt.

6. Overlapping Triangles

When multiple triangles overlap in your 3D model, they are called overlapping polygons. Particularly in SLA printing, this can cause impairments as corresponding areas are exposed multiple times, which is often visible in the final print.

7. Special Considerations for Color 3D Printing

For full-color 3D printing, we require not only a printable 3D model but also the corresponding color information or textures (if multicolor is needed). STL files are not sufficient as they do not contain color information. File formats like OBJ, 3MF, or VRML convey color information and are therefore required for color 3D printing.

If you have any questions or are unsure whether your model is okay, simply upload it. We are happy to provide advice on what improvements may be needed for the model or, if desired, can make those improvements for you.

About 3Faktur: 3Faktur specializes in 3D printing, rapid prototyping, and rapid manufacturing. We utilize HP’s Multi Jet Fusion technology and offer various materials for prototyping and series production. If you have any questions about your project, feel free to contact us.