29.1.2024

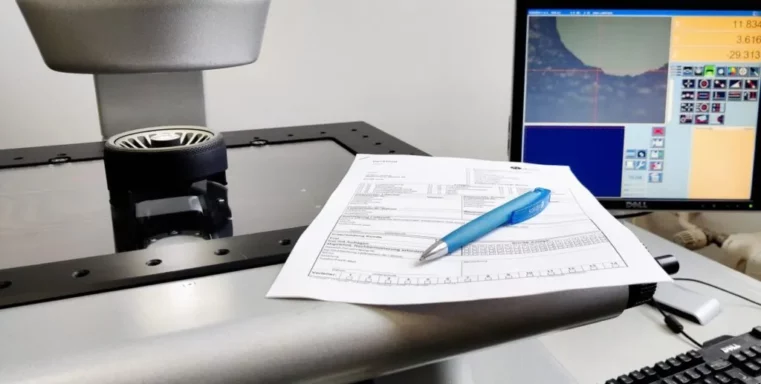

Price differences for 3D printing service providers and cost differences in 3D printing explained

From the variety of printing technologies to the specific requirements of individual processes like Multi Jet Fusion, we cover everything you need to know to better understand 3D printing pricing. Learn how cross-process and process-specific reasons, from the type of machines used to country-specific production costs, can affect pricing. We also look at the critical aspects that determine the quality and cost of production - from work preparation and packing density to cooling time and quality control. Our article not only offers an insight into the technical details, but also provides practical tips on what you should look out for as a user of 3D printing services.

28.9.2023

Technology Overview Color 3D Printing

Until recently, the rule in 3D printing was often, "As long as it's black." But times change, and so has the world of 3D printing. In our latest blog article, we take a look at the exciting evolution of monochrome and full-color 3D printed parts, and the innovative technologies behind them. Learn how you can produce high-quality single-color parts, whether it's by choosing the right raw material or using innovative dip-dyeing techniques. Also discover the world of "full-color" components, from cost-effective solutions to high-end technologies.

25.5.2023

There are a number of 3D printing processes and many more different plastics that can be processed in 3D printing. In this blog post, you will learn interesting facts about thermoplastics and thermosets, their typical properties and specific areas of application. We will inform you how 3D printing works with these plastics and which 3D printing processes and types of plastics are suitable for which specific areas of application due to their special properties.

29.9.2022

Automation in additive manufacturing

3D printing was originally purely a prototyping technology. As the focus is now shifting more towards (small) series production, the automation of additive manufacturing is becoming increasingly economical and sensible. In this article, you can find out which approaches are being pursued and where the industry currently stands.

02.9.2022

Surface treatments of additively manufactured plastic components at a glance

Figure 1: Components during automated shot peening. Source: 3Faktur. The surface treatment technology varies depending on the additive manufacturing technology. In the early days of additive plastic manufacturing, the surfaces of the components produced were rather rough and not up to industrial standards. In the meantime, the surface quality has reached industrial standards. In the interests of the quality and performance of the components, the ...

29.3.2021

ISO/ASTM 52920 - uniform requirements for additive manufacturing

DIN SPEC 17071 is the first guideline for quality assurance in industrial 3D printing. Jointly developed by TÜV Süd, Deutsche Bahn AG, MT Aerospace AG and Siemens Mobility GmbH, the DIN summarizes the holistic testing performance for the requirements of additive manufacturing facilities. The test basis serves the state of the art for quality assurance of production facilities and their services.

26.3.2021

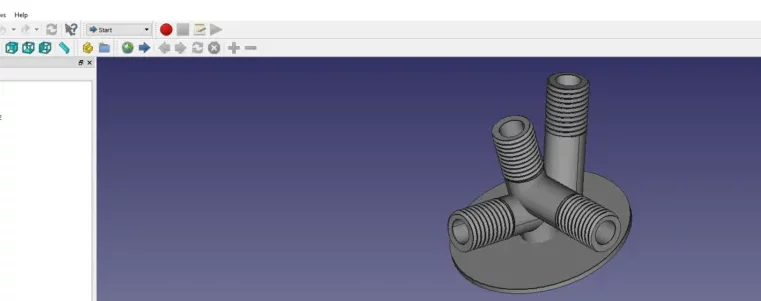

STEP to STL conversion: FreeCAD

Instructions for converting a STEP file into an STL file using FreeCAD, with optimal parameters for 3D printing (Multi Jet Fusion).

14.1.2020

Impact of 3D printing on industrial production

Currently, it is still being debated whether we are currently in the fourth industrial revolution or "only" in the second phase of the third industrial revolution. The technologies of additive manufacturing are an essential part of this development. In this article, we will look at the impact that 3D printing is having on the way we produce.

10.9.2019

The impact of 3D printing on sports

Additive manufacturing methods are becoming interesting for more and more areas of life. 3D printing is playing an increasingly important role in both professional and amateur sports. Users of protective equipment in particular are benefiting from additive manufacturing, but prostheses and individual grips are also increasingly being manufactured additively. Sports equipment or components thereof are now also being manufactured using 3D printing.

07.8.2019

3D printing in the service of the police

3D printing plays an important role in many areas of manufacturing. But 3D printing is also proving its importance outside of industries. Recently, 3D printing has also revolutionized police work, but it also creates new challenges for investigating authorities. In the following article, we will look at how the use of 3D printing technology is facilitating police work.

02.7.2019

Orthopedic insoles with Multi Jet Fusion

Personalized soles are not only important for diabetics. For example, they are also used for other medical problems that affect stability and gait. In addition to purely medically indicated cases, orthopedic insoles also offer ways to improve the patient situation for athletes and people who care about comfort for their feet in everyday life.

28.5.2019

3D models are already required for modern ablative manufacturing processes or for the production of casting molds. However, there are still limitations in terms of design freedom. With the advent of additive manufacturing, the limits of what is possible here have also been pushed back significantly. In the following, we will present three re-design strategies that will help you to exploit the potential of 3D printing.

28.2.2019

A Vision Becomes Reality - The History of 3D Printing

The beginnings of 3D printing date back to the 1980s. As early as 1987, the first commercial 3D printer, the SLA-1 from 3D-Systems, came onto the market. You can find out how the technology has developed up to the present day in this article.

26.2.2019

What happens at a 3D printing service provider between your order and the receipt of your 3D printed workpiece? The following overview shows you which work steps are necessary at 3Faktur for the production of your workpieces - the whole thing using the Multi Jet Fusion printing process as an example.

26.2.2019

Effects of part orientation on the 3D printing result

In 3D printing processes, the orientation of the components in the build space during the printing process plays a major role in the quality of the result. The HP Jet Fusion process does not require any support structures as it is a powder bed process. Capillary effects can occur during the printing process. The heat profiles of the individual components are also an important factor, so component orientation plays a role in the quality of the printed objects.

29.8.2018

The file format STL and its importance for 3D printing

Even though the STL format is around for about 30 years, it is still the single most important format for 3D printing. An STL (Standard Tessellation Language) serves as an interface between the design file (CAD) and the 3D printer. In this article, we explain the technology behind the file format, what programs to use to open the files and possible alternatives of the STL format.

07.8.2018

Industrial applications of plastic 3D printing

3D printing is playing an increasingly important role in industrial manufacturing. At the beginning of the 3D printing boom, the production of prototypes, demonstration objects or spare parts was the main application area of additive manufacturing. Now it is the construction of tools, fixtures, functional components and especially the production of small series. In this article we want to explain the industrial application areas of plastic 3D printing in more detail.

16.7.2018

Current innovations in additive manufacturing

Additive manufacturing is constantly evolving. Technical improvements to existing processes make up a large part of this. In the following article, we have summarized the current trends and analyzed what impact they will have on the 3D printing market.

03.7.2018

Polyamides and their importance for 3D printing

Polyamides are a family of engineering plastics that are used across all industries for demanding applications. They play a prominent role in 3D printing, as they are used in particular in powder-based technologies (laser sintering, multi-jet fusion). We give you an overview of polyamides as such, individual representatives of the group and a brief overview of other typical polymers in industrial 3D printing.

11.6.2018

The properties of 3D printed plastic parts

This article provides an overview over the general properties from parts produced with industrial 3D printers. Learn about the surface properties, mechanic strength, tolerances and other characteristics of additive manufactured plastic parts.

01.6.2018

Fluid Tightness of HP Multi Jet Fusion PA 12 Components

Image: HP Inc. In the past, 3D printing objects were mostly used for rapid prototyping. The progress of additive technologies has led to an expansion in the use of prototypes. In the…

28.3.2018

3D printing in the consumer goods industry

Image: Freshfiber In 2016, the consulting firm PwC conducted a survey to determine if 3D printing would revolutionize households. The result: 60 percent of consumers intended to use this technology at home.…

05.3.2018

For some years now, the term 3D printing has electrified entire branches of industry and also many private users. 3D printing has developed from a sometimes ridiculed niche market into a veritable industry sector. But what is behind the terms 3D printing/additive manufacturing? In this article, we want to shed some light on the jungle of terms.

13.2.2018

3D printing for research, teaching and medicine

3D printing is not only an alternative to established production methods, but also allows the creation of completely new classes of products. One of these novel applications is medicine and science. In medicine, 3D models can make anatomy and pathology literally tangible. In science, the applications are very diverse. We provide an overview of the most important fields of use and applications.

21.11.2017

Overview of the most common 3D printing file formats

The abundance of different file formats that one encounters in the world of 3D printing always leads to uncertainty or confusion. The file formats used depend on which design software was used, which 3D scanner was used and which 3D printer is to be used. The following article presents the most popular file formats and is intended to serve as an orientation in the format confusion.

05.10.2017

Small series, pre-series, pilot series of plastic parts

For over 150 years, people have been using plastics to achieve certain technical properties. A number of processes have been developed to process plastics. Turning, milling and injection molding are the best known and most widely used. Additive manufacturing processes such as 3D printing are the latest methods for processing plastics. Here you will find an overview of the most common processes for the production of small plastic series.

29.8.2017

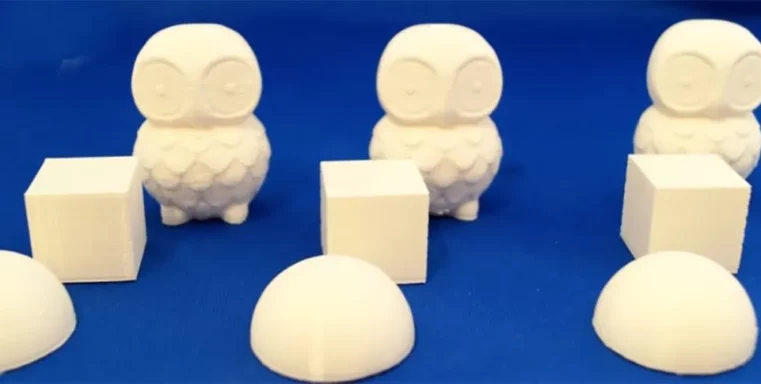

HP Jet Fusion vs. Lasersintern

When HP announced the key features of their new 3D printer ‘Multi Jet Fusion 4200’ in 2014, they promised it would introduce a new kind of additive technology, which would print parts that were more accurate and stronger than those produced by FDM and laser sintering printers – and at ten times the speed. Now that the HP Multi Jet Fusion 4200 has been on the market for a few months, it is time to take an in-depth look at the most important characteristics of both technologies and most importantly, at the quality of the 3D printed parts that they are capable of producing.

08.8.2017

When we talk about 3D printing, the term "reverse engineering" inevitably comes up at some point. Translated somewhat simply, it means something like "reverse engineering". In this article, we will take a closer look at this term and explain the special position of 3D printing technologies in the process of reverse engineering.

24.7.2017

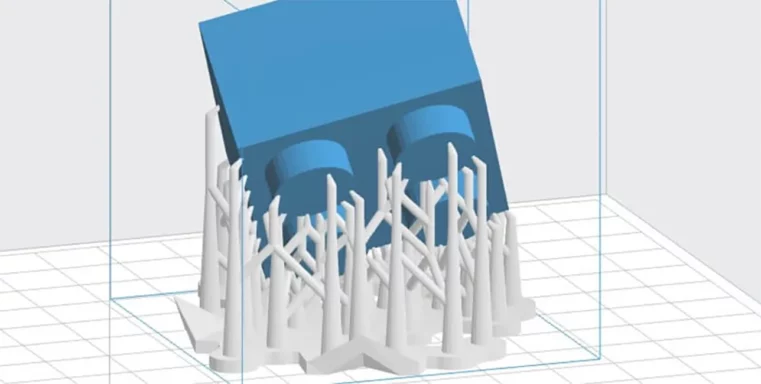

3D printing support structures

Support structures are an important element in 3D printing. They not only significantly determine the price, but also the quality of a component. Not all 3D printing processes require support structures. Some processes use special, often water-soluble support masses. This article provides an overview of the purpose and benefits of structures and the processes in which they play a role.

27.6.2017

Additive manufacturing methods are taking an ever larger place in industrial production. Although some of the technologies have been around for 30 years, the most spectacular developments have only taken place in recent years. This article will discuss the most significant advantages of 3D printing over "traditional" manufacturing methods. Of course, 3D printing cannot replace the established technologies entirely, but if you are aware of the advantages of 3D printing, you can make better decisions regarding the choice of manufacturing method.

13.6.2017

Technological approaches in 3D printing

A large number of technologies have now been "collected" under the term 3D printing. These processes differ in terms of the source material used and the processing method. However, the technologies are often based on the same basic principles. Consequently, not every new process is necessarily a 'revolution', but usually a further development or modification of existing 3D printing technologies.

26.5.2017

The influence of layer height in 3D printing quality

All additive technologies (‚3D printing‘) have in common, that objects are build layer by layer. Therefore, one of the major quality parameters is the layer height in 3D printing. The layer height can be as low as a few microns in DLP or Polyjet machines, or several millimeters in large FDM printers. In this article, you will find an overview of the impact on layer height in 3D printing quality, an overview of the layer heights in popular additive technologies and typical cases, where lower layer heights are helpful or unnecessary.

26.5.2017

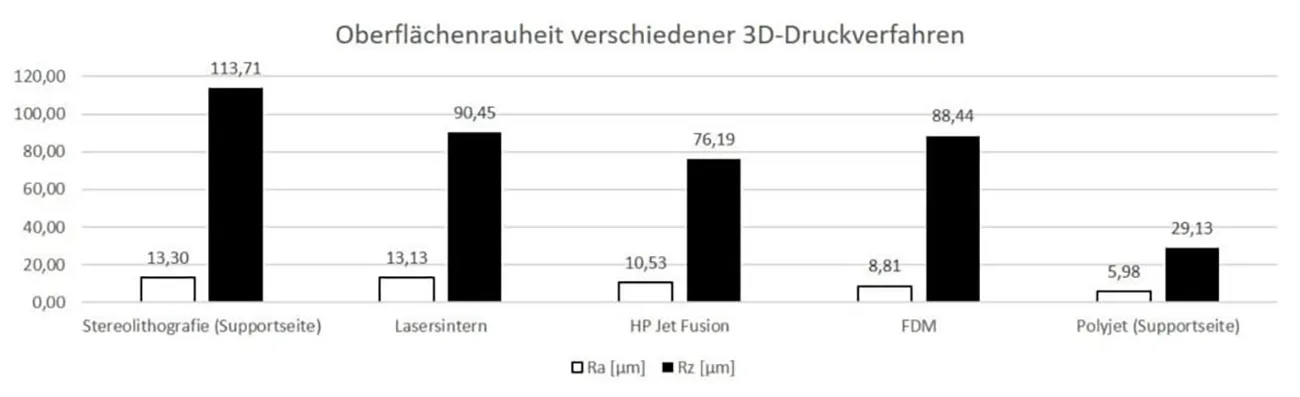

The surface quality of different 3D printing technologies

The quality of the surfaces in the various 3D printing processes varies greatly in some cases. Learn in this article how the 3d printing technologies differ from each other, which factors play a role and which post-processing is possible.

21.4.2017

Injection molding vs. laser sintering: When is which process worthwhile?

Additive manufacturing technologies such as laser sintering have become increasingly efficient and better in recent years. Therefore, the question now often arises as to whether 3D printing technologies can be alternatives to conventional processes such as injection molding. We give you an overview of the quantities from which this is the case and under which conditions.

28.3.2017

3D Printing: Building Block of Integrated Manufacturing

3D printing is an essential component for integrated manufacturing. Learn how and why this is a revolution in the making.

07.3.2017

STL vs. STP - the most popular 3D printing data formats in comparison

If you are in the world of 3D printing, you will inevitably come across a lot of different file formats (.OBJ; .3DS; .STL; .STP; .IGES; .3DM). Out of this multitude, we have picked out 2 file formats that we would like to explain to you in a little more detail: .STL and .STP.

24.2.2017

Avoid mistakes with 3D printing: How to achieve your desired result

3D printing opens up many possibilities, but also has its limitations. In this article, we explain what possible sources of error are and how they can be avoided so that your 3D print turns out the way you want it to.

13.1.2017

Tolerances and machine accuracy in laser sintering (SLS)

In our article Tolerances and Accuracies in 3D Printing, we gave general advice on what to consider when it comes to tolerances in 3D printing. Since questions about tolerances and accuracy arise time and again, especially in laser sintering, we would like to devote this article entirely to this topic. Learn in this article how shrinkage, curvature, etc. affect laser sintering.

14.12.2016

ACCURACIES OR TOLERANCES IN 3D PRINTING

With every new generation of machines, additive manufacturing is getting more precise, cheaper and faster. However, tolerance comparable to CNC technologies cannot be achieved yet. In this article, we introduce you to tolerances in 3D printing: what are realistic accuracies and what are the most important factors.

07.12.2016

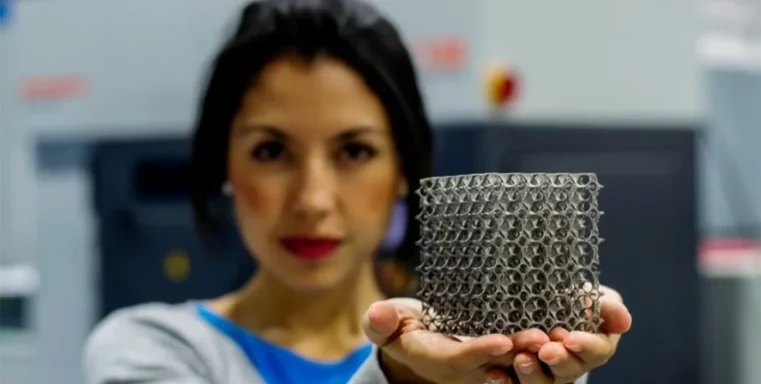

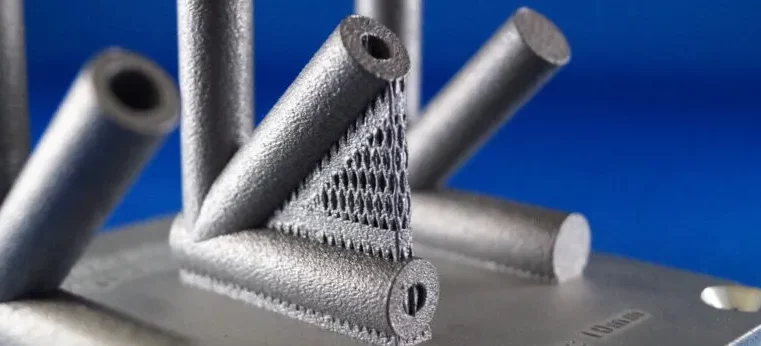

Direct Metal 3D Printing: Process, Technology and Application

Sales figures and the willingness of industries to invest in additive manufacturing of metal prove that this technologies possibilities and importance are growing: Investments: A study of KMPG, an auditing company in Germany, shows that nearly 25% of managers in metal sectors invest in additive manufacturing and 27 % of industries which already have such ...

14.10.2016

How to create molecule models for 3D printing

Over the last few decades, we have been able to significantly improve our understanding of the three-dimensional structure of large molecules, like nucleic acids and proteins, and how this relates to their function. With resources like the Protein Data Bank or the Nucleic Acid Database, in combination with modifiers such as Pymol, Chimera, JSmol and ...

24.3.2016

3D printing in application: spare parts created with 3D printing

Additive manufacturing methods have a very broad field of application and are used both for the production of prototypes ('rapid prototyping') and increasingly for (small) series production ('rapid manufacturing'). One area of application that is gaining in importance is 3D printing of spare parts. Especially for older machines, for very complex components or if there are no more 'original spare parts', 3D printing is usually a worthwhile option to create replacements.

17.2.2016

3D RAPID PROTOTYPING: METHODS AND APPLICATIONS

Rapid prototyping (RP) is currently on everyone's lips, with many researchers saying that the technology is one of the defining megatrends of the near future. But what does this term actually mean? The term rapid prototyping has established itself as a generic term for many 3D printing applications.

09.2.2016

Depending on the shape and use of the object, a variety of materials are available for your 3D print. The most commonly used materials are photopolymers/resins (e.g. for SLA or PolyJet), metal powders (e.g. aluminum, titanium, steel), plastic powders (e.g. PA 12, TPU) and plastic filaments (e.g. ABS or PLA), but also food ... more

04.1.2016

3D programs for beginners & advanced users

3D printing offers fascinating possibilities - if you are able to create a suitable 3D model. This is certainly not easy at first, but once you have mastered it, you can use your 3D printer or our 3D printing service to create your very own personalized products!

05.11.2015

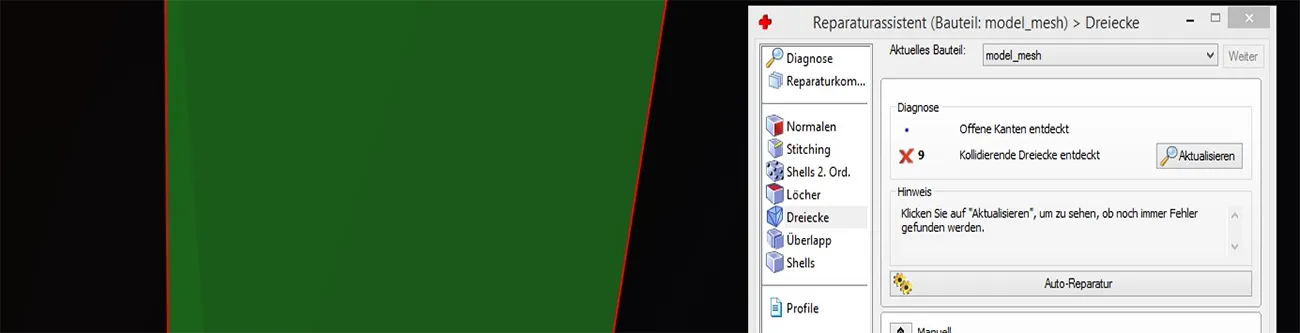

How to create 3D models for 3D printing

Unfortunately, not all 3D models are suitable for 3D printing. Whereas for virtual applications, for example, it is quite sufficient if the 3D model is visually impressive, certain criteria must be met for 3D printing. These include, of course, that shape and (in the case of color 3D printing) color are defined, but there are also other criteria that are crucial.We have compiled the most important design criteria for you:

27.10.2015

The best sites to download 3D printable Models

3D modeling is a lot of fun, however, it takes quite some skills to master it. If you are short of time or lack the experience in creating your own 3D printable file, you can check 3D printing databases for existing models. There are plenty of databases for 3D printable models out there, in this article, we introduce you to the most important ones.