Possible Materials

Depending on the shape and use of the object, a variety of materials are available for your 3D printing needs. The most commonly used materials include photopolymers/resins (e.g., in SLA or PolyJet), metal powders (e.g., aluminum, titanium, steel), plastic powders (e.g., PA 12, TPU), and plastic filaments (e.g., ABS or PLA), but food materials are also possible. While metals and plastics are most interesting for industrial applications, processes that extrude materials through a nozzle are perhaps the most exciting for consumers. Significant advancements have been made in this area in recent years. For example, since 2015, you can customize your own gummy candies in Berlin. Or perhaps you prefer small artworks made of sugar, in which case 3D Systems Culinaria is the place for you. And if that’s not enough, you can have all kinds of wonderful creations made from food materials by the experts at Procusini with their food 3D printers.

In processes that require a powder bed for 3D printing, theoretically, a variety of source materials are possible. The basic requirement is that the material can be processed into a very fine powder. So far, metal and plastic powders have been established for Selective Laser Melting (SLM), Multi Jet Fusion (MJF), and Selective Laser Sintering (SLS). However, experiments are also being conducted with other powder materials, including wood shavings, ceramic powders, and even bone meal for creating implants.

If you would like to learn more about the most commonly used materials, here is an overview with additional links to our material pages.

Fantastic Shapes

3D printing is a relatively new manufacturing process and an umbrella term for so-called generative manufacturing processes. Generative manufacturing processes allow for the representation of almost any shape. This includes chain links, overlapping, and twisted structures. The latter is not feasible or extremely difficult to achieve with processes like injection molding or CNC methods.

In 3D printing processes that work with a powder bed, such structures are usually easily replicable as hollow spaces can be left between the structures. However, for manufacturing methods without a powder bed, support structures must be printed for overhanging structures. This is not usually a problem for most 3D printers, as support structures can typically be easily removed after 3D printing. The various 3D printing processes offer different levels of detail. PolyJet and SLA processes allow for very fine details. Some compromises must be made with Multi Jet Fusion, while FDM processes require greater compromises in detail levels. However, the possible shapes and level of detail depend not only on the chosen printing process but also on the chosen material. It’s best to consult your 3D printing service provider if you’re unsure which process and material are best suited for your object.

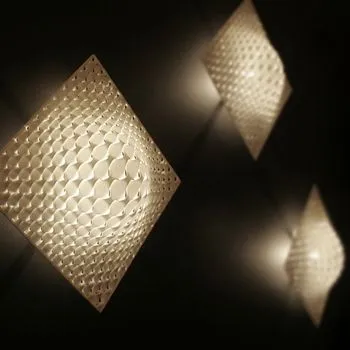

Below are a few examples of shapes possible with 3D printing techniques.

Applications of 3D Printed Products

Due to the different manufacturing processes and materials used, various applications arise for 3D printed products. Objects made of metal or PA 12 can be used as functional models or components. Titanium and PA 12 also exhibit biocompatibility, meaning 3D printed products made from these materials can be used on (PA 12) and even inside (titanium) the human body. Customized foods are eye-catching and a nice change for everyday life. They also offer practical benefits. Using a 3D food printer, you can prepare food for people who, due to physical reasons, can only consume pureed food in a way that resembles the original (unpureed) food. Many companies (Siemens, Volkswagen, etc.) also use 3D printers to produce small series or special spare parts and have been able to reduce the repair time of some components by up to 90% through the use of this technology. The major advantage of 3D printed products is the quick availability of the model, component, or spare part. If a printable 3D model is available, a production time of one to two days is the norm. This can significantly accelerate the development process and save development costs. An industry sector has emerged around the rapid production of prototypes, which has been given its own designation with “Rapid Prototyping.”

That’s Currently Not Feasible

3D printing methods are particularly suitable for individual productions (prototypes, models) and small series. The size of the build volume of the 3D printer limits the dimensions that a 3D printed object can have. So, if larger objects are to be printed, they must be printed in different steps, independently of each other, and later assembled. But even in this area, there seems to be no end to development in sight. The WASP project from Italy has once again pushed the boundaries of what’s possible in terms of enlarging the build volume with the BigDelta.

Additionally, with the current state of technology, it’s still not possible to print electronic products. Objects made of both metal and plastic also cannot yet be printed in one piece. The metal parts and the plastic parts must be printed separately and assembled later. While simultaneous 3D printing with different plastics is already possible, the combination of metal and plastic is still futuristic.

About 3Faktur: 3Faktur specializes in 3D printing, rapid prototyping, and rapid manufacturing. We utilize HP’s Multi Jet Fusion technology and offer various materials for prototyping and series production. If you have any questions about your project, feel free to contact us.