3D printing technologies have already provided a boost to many industries. In this post, we want to explore the possibilities of 3D printing in the field of orthopedics/medical technology. Specifically, we will focus on the patient-specific production of orthoses and prostheses. Additionally, 3D printing offers exciting opportunities in the design of prostheses and orthoses, allowing them to be proudly displayed rather than hidden away.

Used Processes for 3D Printing in Orthopedics

In the case of orthoses and most other aids worn or attached to the body, plastic powder bed fusion processes are used, particularly HP Multi Jet Fusion (standard and full-color) and laser sintering. The polyamide 12 (PA 12, ‘Nylon’) used in both processes enables the production of durable, biocompatible, and acid-resistant orthoses. It is also easily post-processed, allowing orthopedic aids to be customized according to patients’ preferences. An essential advantage of powder bed fusion processes is the ability to produce nearly any shape and geometry. Furthermore, the production typically takes only a few days (usually 3-5 working days), which can significantly shorten processes in orthopedics. For objects that enter the body, metal 3D printing is typically used, with titanium being particularly popular due to its biocompatibility, stability, and durability.

Applications

Orthoses

An orthosis is an artificially produced object used for stabilizing, correcting, or immobilizing limbs or the trunk. The advantage of 3D printing technologies is that they eliminate the need for plaster casts. The required data is obtained using 3D scanning technologies without direct contact with the body. Another possibility is the parametric design of 3D models based on existing measurement data. The result is an almost perfectly fitted orthosis that can also be customized according to the patient’s aesthetic preferences (choice of colors, decorations, accessories). This transforms the orthosis into a functional piece of jewelry that is no longer hidden but proudly showcased in everyday life.

Shoe Insoles

A special case of orthoses is orthopedic insoles used in shoes. These insoles were previously mass-produced and tailored to specific recurring orthopedic conditions. By using 3D scanning technologies, the data can be quickly and non-invasively obtained for each patient. Traditional insoles can then be manufactured based on the acquired CAD data. However, the advantages of 3D printing can also be utilized here (speed, resource efficiency) by 3D printing the insoles. Currently, selective laser sintering (SLS) is usually used for this purpose. However, instead of the commonly used PA 12, the soft, rubber-like material TPU is typically used.

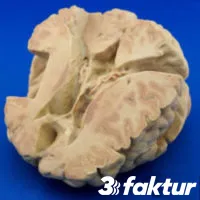

Surgical Preparation

For complex/unusual surgical procedures, the ability to “practice” the procedure on a model provides a tremendous advantage for its success. A 3D model is printed based on CT data, allowing certain operations to be practiced in advance. This particularly enhances the chances of success in surgeries involving heart defects in infants/young children. Using a color 3D printer (e.g., HP Jet Fusion 580), the models can be made even more illustrative.

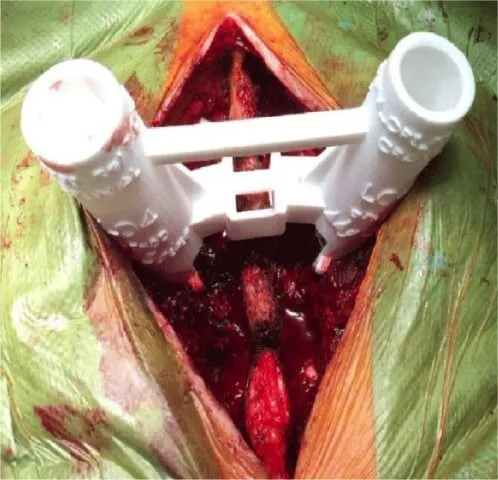

Surgical Tools

As biocompatible and sterilizable materials for 3D printing are now available, a wide range of possibilities is opening up for medical applications. Specifically tailored surgical tools are already being 3D printed. Additionally, individual drilling guides, screw plates, clamps, templates, and other aids for surgical procedures are now 3D printed. The greatest advantage of using these surgical aids lies in the time saved during the procedure since the positioning of the aids has already been precisely determined in advance.

Image: Delfini R., J Spine; 2015;4: e118

Training Models

In the field of education/research, complex models are already being printed for demonstration and practice purposes. The advantage here lies in the ability to represent sophisticated geometries relatively affordably and provide the viewer with a more detailed insight into the structure and composition of body parts. Particularly for extraordinary pathological cases, cost-effective demonstration models can be produced. Color 3D printing allows these models to be produced in full color, with important elements highlighted.

Conclusion

Whether it’s shoe insoles, stabilizing splints, or other orthopedic aids, 3D printing technologies take the production of orthoses to a higher level. The products can now be manufactured faster, customized, and adapted to patient requirements. Additionally, 3D scanning technologies provide a precise and non-invasive means of quickly obtaining the required data. In the field of prostheses, there are ongoing advancements, and it remains exciting to see the future impact of 3D printing on orthopedics.

About 3Faktur: 3Faktur specializes in 3D printing, rapid prototyping, and rapid manufacturing. We utilize HP’s Multi Jet Fusion technology and offer various materials for prototyping and series production. If you have any questions about your project, feel free to contact us.