- A material is deposited layer by layer.

- A material is in powder form and is fused layer by layer.

- Flexibility in production: Economically viable for batch size 1; product changes possible almost anytime.

- Speed: Shortening of the development process and time-to-market.

- Design Freedom: Virtually no design restrictions and individual product customization possible.

- Efficiency: Low material consumption and minimal inventory needs due to near Just-in-Time production.

New Business Models

An essential element for the democratization of production is 3D printing service providers like 3Faktur. This makes production more local, faster, and more flexible, especially for SMEs and startups, but also for everyone else. New companies and business models are also emerging in the field of 3D model development and provision and in the software sector.Process Chains

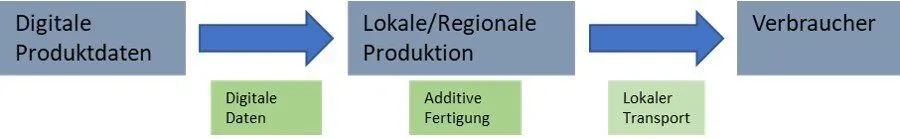

3D printing also has an impact on global process chains by shortening them and re-regionalizing them. This brings production closer to the point of consumption. Regionalization and decentralization will also make it possible to respond more quickly to changing customer demands. Storage will also become almost unnecessary as products will be manufactured when needed. “Old” process and supply chain for global mass production of physical goods: “New/Shortened” process and supply chain for locally produced individual goods:

“New/Shortened” process and supply chain for locally produced individual goods:

Sustainability

Closely connected with the regionalization and shortening of process chains is the possibility of producing more sustainably. In almost all steps of the 3D printing process chain, 3D printing makes a noticeable contribution to sustainability:- Pre-production: Hardly any tools required.

- Production: Partially drastic reduction in the number of components.

- Inventory management: Less material consumption, less logistics required.

- Product design: Weight and shape optimization, reduced energy and material consumption.

- Service and maintenance: Spare parts are manufactured when needed, reducing inventory and maintenance of components significantly.

3D printing is in the process of revolutionizing the way production is carried out. Its impact goes far beyond pure production and also affects areas such as product design, logistics, inventory management, and service. Furthermore, additive technologies also have a noticeable influence on the workforce.

About 3Faktur: 3Faktur is a specialist for 3D printing, rapid prototyping and rapid manufacturing. We work with HP’s Multi Jet Fusion process and offer different materials for prototyping and serial production. If you have any questions about your project, please feel free to contact us.